Hello whoever decided to click on this!

I'm Joe and I keep finding myself caught up in the idea of wanting a little steam engine to play with as I have been tinkering with other alt energy projects too.

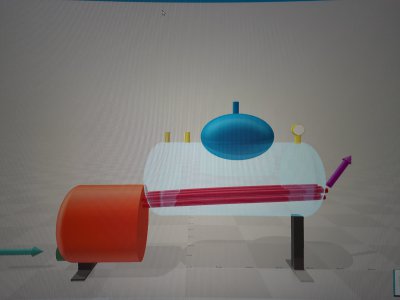

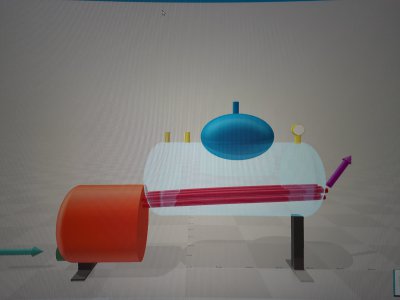

Anyway today I hopped on my computer and downloaded a modeling program to try and draw out what I have in mind.

Idea is pretty basic. Take a 40# propane tank run between 5 and 9, 1-1.5" diameter steel fire tubes through it welded on the ends at a slight upward angle 3-5*. Not planning to exceed 50psi in operation and the plan would be to have 2 pressure relief valves at 60 and 70psi as failsafes. Have heard enough of the horror stories of cookin off a boiler to a couple hundred lbs and making a nice big pressure bomb.

Then for a firebox a second propane tank, lop off the top few inches to make the steam dome on the boiler tank which gives the advantage of a preinstalled bung and valve for the outlet. Flat plate on the cut open with the fire tubes welded in. And a 3-4" intake opening on the burner depending on how many pipes it works out needing. Aiming for a bit bigger intake than the overall tube area (I think anyway)

Undecided on lpg or coals/wood as a fuel but propane makes the most sense with a cleaner burn and adjustability, less tube maintenance. Also fitting being a propane tank boiler.

End goal would be to drive a 2 stroke engine from something like a weedeater and try to turn a small 180w motor I have. Just for the fun mostly

I'm Joe and I keep finding myself caught up in the idea of wanting a little steam engine to play with as I have been tinkering with other alt energy projects too.

Anyway today I hopped on my computer and downloaded a modeling program to try and draw out what I have in mind.

Idea is pretty basic. Take a 40# propane tank run between 5 and 9, 1-1.5" diameter steel fire tubes through it welded on the ends at a slight upward angle 3-5*. Not planning to exceed 50psi in operation and the plan would be to have 2 pressure relief valves at 60 and 70psi as failsafes. Have heard enough of the horror stories of cookin off a boiler to a couple hundred lbs and making a nice big pressure bomb.

Then for a firebox a second propane tank, lop off the top few inches to make the steam dome on the boiler tank which gives the advantage of a preinstalled bung and valve for the outlet. Flat plate on the cut open with the fire tubes welded in. And a 3-4" intake opening on the burner depending on how many pipes it works out needing. Aiming for a bit bigger intake than the overall tube area (I think anyway)

Undecided on lpg or coals/wood as a fuel but propane makes the most sense with a cleaner burn and adjustability, less tube maintenance. Also fitting being a propane tank boiler.

End goal would be to drive a 2 stroke engine from something like a weedeater and try to turn a small 180w motor I have. Just for the fun mostly