SNIP.. (1)The metric lead screw fits me well, because I have to do mostly metic threads anyway.

(2) As for the threading with a hand die, Ruben mentioned, that the machine stopped instantly. Would it be possible to do this thread by just turning the chuck by hand back and forth?

(3) I read some about the threading dial and this begins to sink in. Would it be possible to find the beginning of the thread also with precise DROs?

As fort you readouts, Ruben, I'd like to go with real good ones. I saw them on e-bay for about 400 with a big setting box . . .

The question is, if the scales fit in/under the SC-4?

They have slim-scales which could fit, but I don't have any measurements from the lathe.

(4) Ruben, if I supply you with possible measurements from the scales, would you be able to see, if they fit?

1. The metric lead screw does NOT mean that you can't thread other threads. Most NC & NF threads can be cut just fine. The thread form for metric and SAE is the same, just the diameter and threads per inch is different, so its pretty easy, and the machine comes with a huge number of threading gears to cover a very wide range of threads.

2. I tried to do just that, using the chuck key for extra leverage. Just spun the rod in the chuck. I had two things going against me. I was threading tool steel, very hard, and I was trying for 100% threads. I should have turned the rod smaller, and settled for 50% threads, OR used a cutter for normal threading. After I got the rest of my cutting bits, threading wasn't much of an issue, using the machine as intended. The big difference is that you can control the depth of cut, whereas with the taps and dies, the depth of cut is fixed. Also, I was stupid for trying for 100% threads, 50% is plenty strong enough in steel, and much easier to cut. Although I rarely use aluminum, I'd go 75% thread there. The threading process using the intended procedure on this machine isn't really tough to master, just giving you the pro's and con's of this machine. For hobby use, the extra time spent threading vs a machine with a threading dial is really no issue. For any high volume situation, where time is money, that would change, but then you'd likely be talking a different process anyway, at the very least a CNC machine.

3. I don't know. I suspect that would be an exercise in frustration, too much chance of ruining a workpiece. The intended procedure works fine.

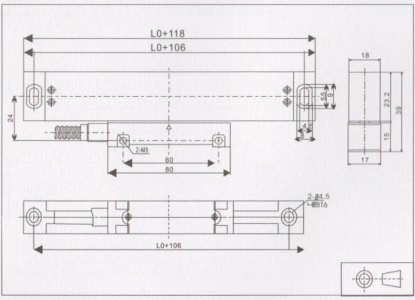

4. I'd be happy to measure whatever you need, BUT on the condition that I not be responsible for any issues that might result from that. The scale for the carriage should be no issue, as there is lots of room on the back side of the machine, as long as you get the sending unit reasonable centered.

With a little trimming of the splash guard near the motor, up to 23.75" should fit. It "looks" like almost another inch should be available with slim enough scales, but I think thats deceptive, as this lathe has a big plate in the middle of the back side of the bed (I think used for the mill mount when equipped as a 3 in one machine, lathe-mill-drill) that requires the scale to be mounted with about .250" extra clearance from the rest of the bed.

EDIT: I should have said: Without any trimming of the splash guard, or overlapping the mounting tab on the tailstock end, 20.75" is available. With the tailstock removed, carriage travel is 17.375" . My I'gage reader is 3.0" plus a half in each for the two mounts, so you need a minimum of space of 21.375, which is why the splash guard must be trimmed.

For the cross slide, I used an aluminum bar stock to extend the slide an extra few inches (due to the really deep splash guard, this is no problem), because I wanted to offset the read head so the tailstock could never hit it. Works fine, and I only lost about .600" carriage travel when the tailstock is mounted, and of course full travel without the tailstock mounted.

I didn't bother with a DRO readout for the ompound, because its usually set at an angle, which would tend to make any reading, other than a set zero, nearly meaningless.