- Joined

- Dec 30, 2014

- Messages

- 259

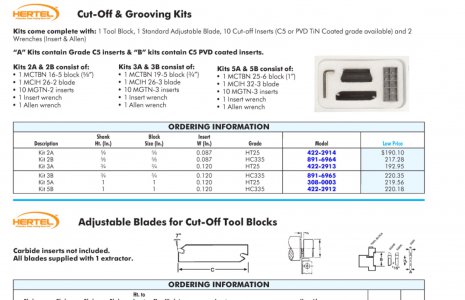

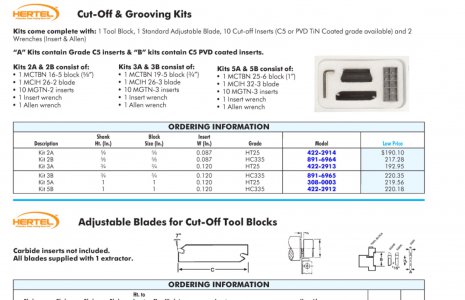

I want to try one of these or similar type carbide insert cutoff tools. Do I need the entire set with the tool block or will the blade fit my AXA QCTP parting blade tool block? I can't tell if there is some special profile to the blade or the tool block that makes it proprietary? If I don't need the tool block it save a bit of money so I can buy other fun stuff!

If you didn't get the memo, ENCO has 20% off today only!

Thanks,

Jim

If you didn't get the memo, ENCO has 20% off today only!

Thanks,

Jim