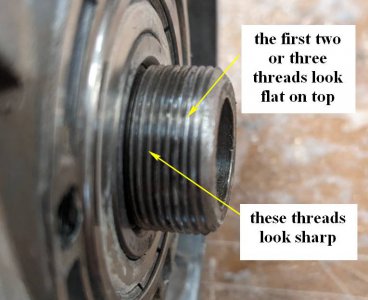

Seized the main bearing in this 3.25hp router motor last week. I ordered new bearings, tore it apart and put it back together - wrong. So i had to take it apart again. During the second disassembly i must have done something to the fine threads on the armature in the first picture: it fit the first time, but not the second. The collet nut is hardened steel, and aside from some adhesive in the threads which i mostly cleaned out looks fine. The threaded end of the armature is not hardened, so i carefully chased the threads with everything i could think of. The collect nut threads on 1/4-1/2 turn and then locks rock solid. i fussed and fussed the threads, eventually chamferering the whole thing with a file (as seen in picture) in an attempt to get the nut to thread on. No go. finally i bolted the motor down and visually checked the concentricity of the armature threads: they seem fine. No mater how i try to thread the collet nut on it does not appear to go on concentric, so it must be cross threaded? but i cannot get the thing on straight. I'm at a loss and need the motor going for work. any suggestions? I have a benchtop mill, no lathe.

I tried to order a replacement, but apparently this size motor is a sudden rarity in the post-covid wold. I cant find one that fits inside the machine that is in stock anywhere.

Extra credit:

The bearing is press fit onto the armature (very tight), and pressed into the aluminum router body so the alunumum body is sandwiched between the collet and some internal fan parts on the armature. the bearing is retained with a plate that mounts to the outside of the aluminum router body (though as i said, very tight, i cant imagine it moving). What would the proper method be for removing it and reinstalling the bearing? Anyone have a recomendation on a bearing puller kit that is above the el cheapo grades? i've got lots of european machines that will probably need maintenance and i'd like to be ready to do it right. Automotive size kits seem a bit big. My max bearing sizes are probably 4"/120mm.

I tried to order a replacement, but apparently this size motor is a sudden rarity in the post-covid wold. I cant find one that fits inside the machine that is in stock anywhere.

Extra credit:

The bearing is press fit onto the armature (very tight), and pressed into the aluminum router body so the alunumum body is sandwiched between the collet and some internal fan parts on the armature. the bearing is retained with a plate that mounts to the outside of the aluminum router body (though as i said, very tight, i cant imagine it moving). What would the proper method be for removing it and reinstalling the bearing? Anyone have a recomendation on a bearing puller kit that is above the el cheapo grades? i've got lots of european machines that will probably need maintenance and i'd like to be ready to do it right. Automotive size kits seem a bit big. My max bearing sizes are probably 4"/120mm.