Either I'm getting too tired to be writing or too old, but Kelly had already answered the tension lever direction question so just disregard the next small paragraph.

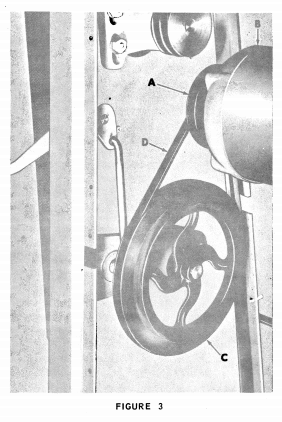

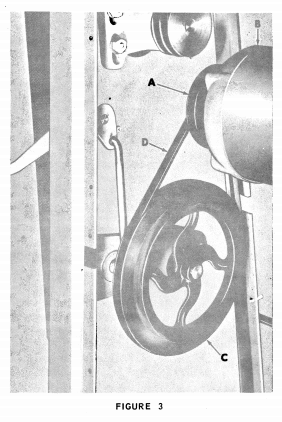

@MHW, are you referring to the 3986 or the 3996? I don't really know about the 3986 but on the 3996, no. You push the outside-mounted lever down to tension and pull it up to release. That's the way that mine was when I bought it soon to be 40 years ago. Be advised that the thing doesn't want to stay all of the way up. I thought about trying so see whether or not I could reverse that but concluded that it was more important that it have no tendency to come loose while running than while not running.

The (actually two) other parts books were for a 3986, not a 3996. The 3985 and 3986 were the 24" and 36" bench models. The 3995 and 3996 were the 24" and 36" cabinet or as Atlas or Clausing called them, pedestal models. The only differences between the 24" and 36" were the bed, lead screw and rack lengths and part numbers. Besides the cabinet or no cabinet, the only other differences between the bench and cabinet models were the rear-mounted or the underneath mounted motors and 8-speed countershafts. And the spindle pulleys. The bench models had the 4-groove cone pulley and the cabinet model had a 2-groove one. The cabinet model also had two spindle drive belts, both the same size. Other than those points, the four lathes were exactly the same.

I spent some time yesterday deleting the extra 3986 manual and the correcting a few errors in the remaining ones. Most errors might be considered only cosmetic. But the stub sticking out of the top of the cross feed nut was drawn almost as large as the exposed part whereas it is really about one-half the diameter. The carriage gib was drawn as about half as long as it really is.. And I also replaced the bed and lead screw page with the one that I cleaned up and corrected several years ago for the 3996. For one thing, there is a single socket head screw shown above the bed. It was added during production to help hold the QCGB on. And if you don't know about it and try to remove your gear box, you will be pulling your hair out trying to figure out why it won't come off. It is well hidden down inside of the headstock. Anyway, I think that the two manuals are now both correct. Anyone who had previously downloaded either one should download the revision.

Back to the belts for the 3996, the one for the cone pulleys and the motor belt are standard FHP belts. 4L410 for the cone pulleys and 4L360 for the motor. The two belts for the spindle are A42's, not 4L430's. These are for some reason 43" long but the "A" belts are called Multiple V-belts, have a tighter length tolerance or variation, and are designed to run with up to either 8 or 12 belts in parallel. These are what came with my lathe new and are the same as what I got from Clausing 3 or 4 years ago.