- Joined

- Feb 4, 2021

- Messages

- 11

Hello everyone,

I recently acquired a Hardinge HLV lathe (one of the very first factory models with S / N 0052 - probably 1949 from my sources). The previous owner had already done a lot of restoration on it but I still have work to do to restore it completely.

I have never worked on a metal lathe so I am a complete beginner in the field. I will already give you the little things done on this beautiful object.

For now, here is what I have been able to do since January 1st:

- electrical rewiring of the main box

- remake an old backelite screw (3D printing) to keep the motor coals in advance

- repaint the feed motor

- connect the main safety switch

- remake the box and longitudinal advance lever of the carriage

- remake the eccentric screw which holds the upper carriage

- change the starter and the feed motor variator switches

- paint the lamp

Here some photos of the work done :

Redraw of the plate (I print it on glossy paper, glue and cover it with epoxy) :

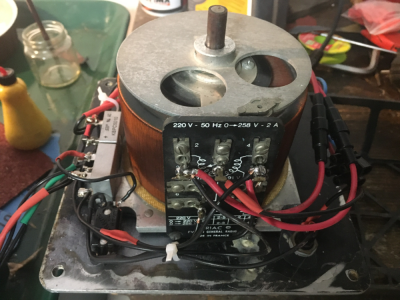

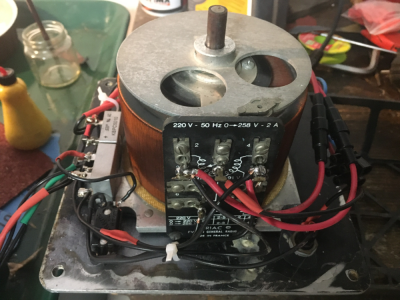

Before and after (new wiring, new variac, I add fuses, new "old" switches):

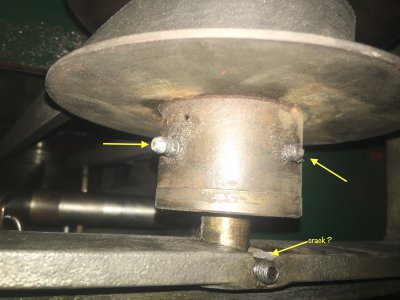

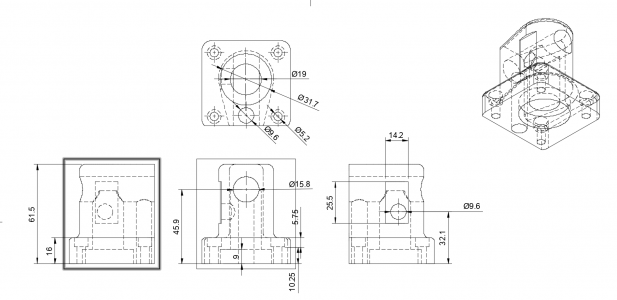

Here is the missing "clutch box" on the left

I paint it :

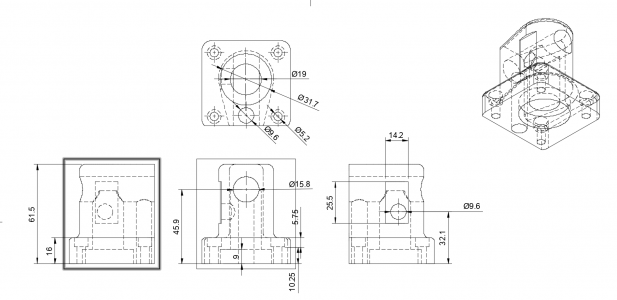

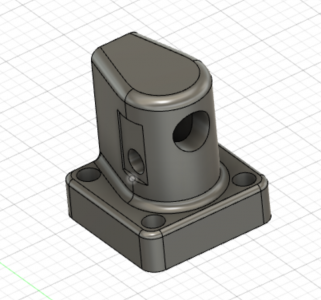

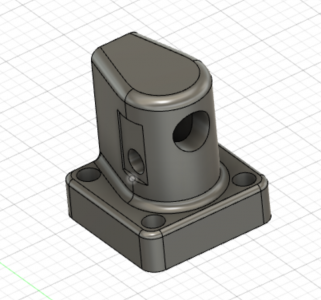

So I draw it on Fusion 360 :

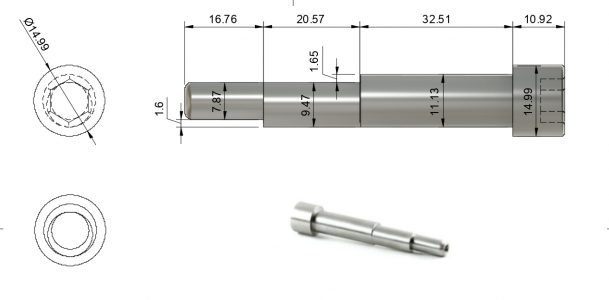

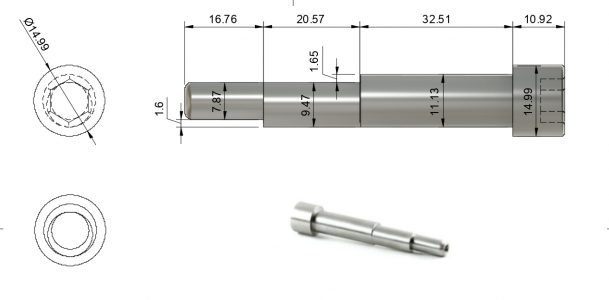

An ask somebody (in France) to make me a new one. during this time, i realize my first real shoot :the axis of the clutch (from scratch).

I drew the missing Hardinge Plate :

I recently acquired a Hardinge HLV lathe (one of the very first factory models with S / N 0052 - probably 1949 from my sources). The previous owner had already done a lot of restoration on it but I still have work to do to restore it completely.

I have never worked on a metal lathe so I am a complete beginner in the field. I will already give you the little things done on this beautiful object.

For now, here is what I have been able to do since January 1st:

- electrical rewiring of the main box

- remake an old backelite screw (3D printing) to keep the motor coals in advance

- repaint the feed motor

- connect the main safety switch

- remake the box and longitudinal advance lever of the carriage

- remake the eccentric screw which holds the upper carriage

- change the starter and the feed motor variator switches

- paint the lamp

Here some photos of the work done :

Redraw of the plate (I print it on glossy paper, glue and cover it with epoxy) :

Before and after (new wiring, new variac, I add fuses, new "old" switches):

Here is the missing "clutch box" on the left

I paint it :

So I draw it on Fusion 360 :

An ask somebody (in France) to make me a new one. during this time, i realize my first real shoot :the axis of the clutch (from scratch).

I drew the missing Hardinge Plate :