- Joined

- Dec 2, 2012

- Messages

- 1,723

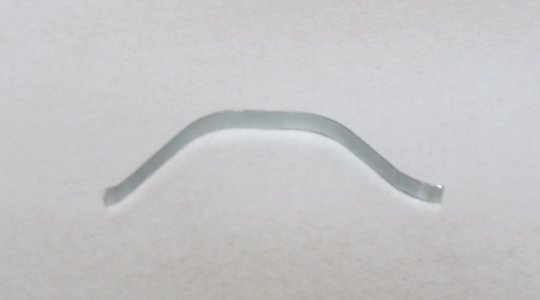

I've used a bent cut down old hacksaw blade as a spring to keep the thin parallels against the jaws, saw it somware on the internet and lodged it in the memory for future use, good idea to run a grinder over the teath first

If your going to cut down the parallels they might not provide such good support, I guess it depends how the slide on ur vice is designed.

Stuart

If your going to cut down the parallels they might not provide such good support, I guess it depends how the slide on ur vice is designed.

Stuart

Steve Shannon, P.E.

Steve Shannon, P.E.