- Joined

- Nov 27, 2012

- Messages

- 7,858

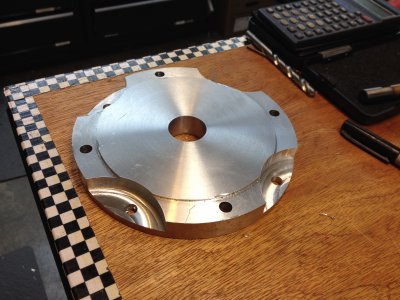

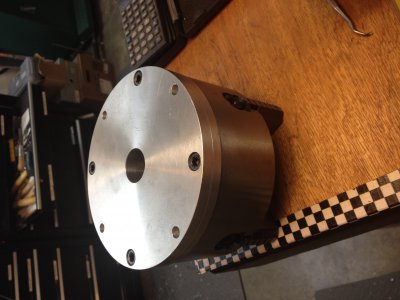

Yes, that is why you have to step down one size on the chuck if using a backplate. That leaves room for mounting bolts for the backplate to to the RT. So in your case you would run a 5" chuck. I would look for a front mount chuck even if if it costs a bit more. That way you won't have to mess with a backplate & gives you larger capacity with the 6" chuck (front mount).