I prepared to have my shop floor epoxied. Very very unfortunately my G4016 lathe tipped. not cool. among a few problems, the speed selection levers broke. I was able to get them welded and ready to reassemble. I find the drawing in the manual not too helpful. I wish I took a picture beforehand, but I did not. Would anyone be willing to take off the front of the travel speed box and take a picture or two? I don't understand the placement of the small spur gear. Plus the gears above the C axle slide back and forth, that doesn't seem right.

Any help would be very appreciated.

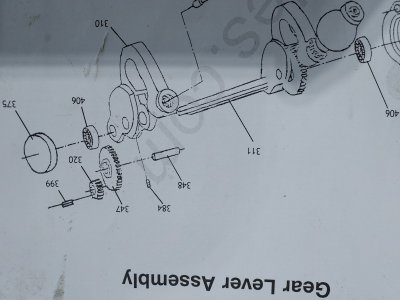

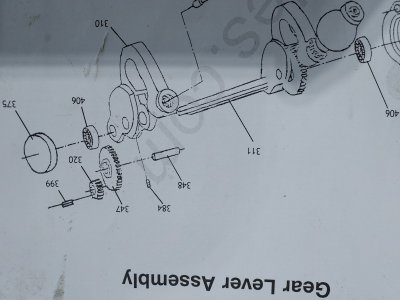

the attached images show my issue - how to assemble the speed control levers/axle. I have no idea where gear 320 goes. sorry about the picture upside down.

Paul

Any help would be very appreciated.

the attached images show my issue - how to assemble the speed control levers/axle. I have no idea where gear 320 goes. sorry about the picture upside down.

Paul