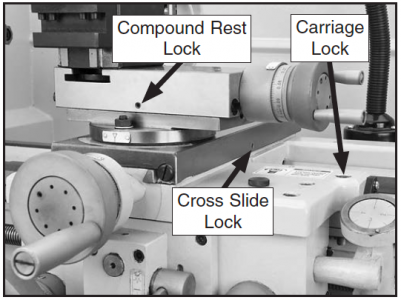

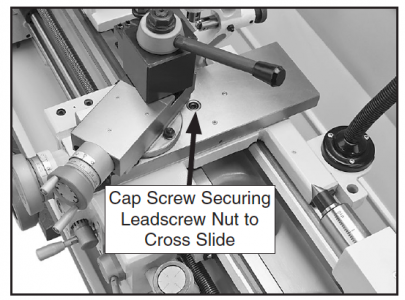

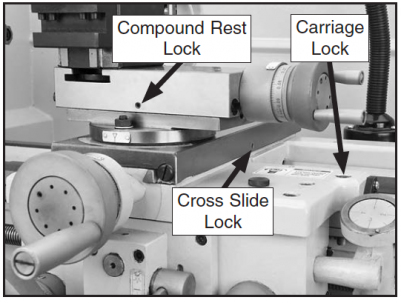

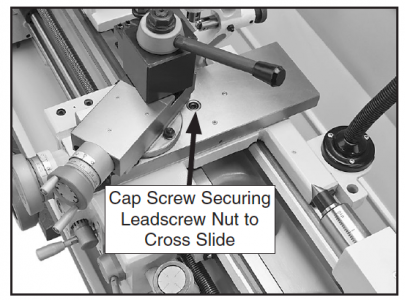

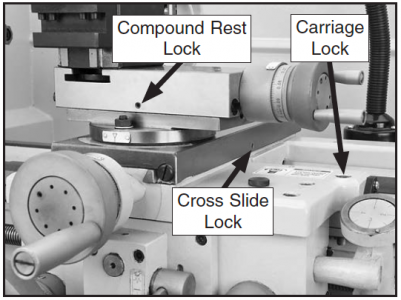

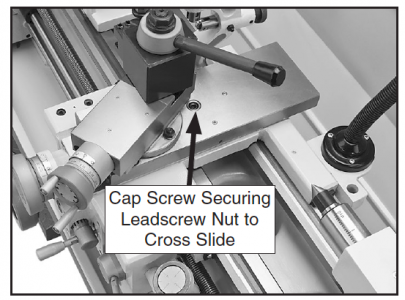

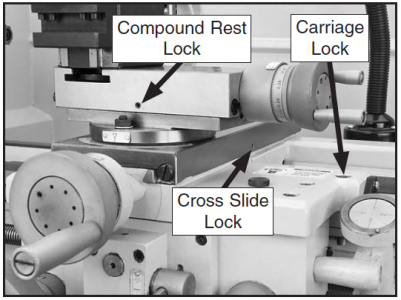

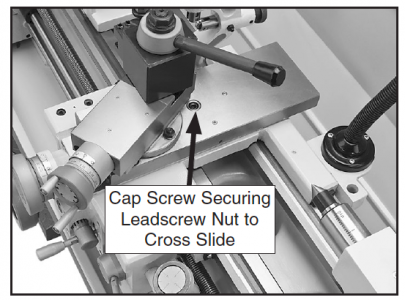

Recently acquired a G4003g , used but in great condition. The cross slide lock set screw was missing, so I replaced it. But in noticed turning the cross slide and compound lock set screws all the way in only adds a little resistance to the gibs? There was a recent related thread on this: http://www.hobby-machinist.com/threads/g4003g-lock-on-the-compound.25680/ what I am wondering is there a pin or something that goes beind the set screw that actually does the tightening? I have to thread them in a long way before the bind.

Thanks

Thanks