I've got a Grizzly G0758 (albeit with another name on it). I got it a couple of years ago and I promptly stripped the teeth of the two speed plastic gear...

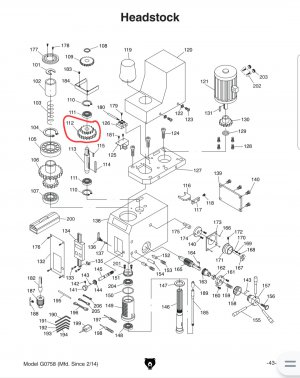

That's the item no 112 here:

I got a new one under warranty, but I had no time to swap it so I kept using the mill on the high gear only. Few years later I replaced this gear finally so now I have low range too. I was firmly decided to never use any flycutters, or any big cutters on that mill.

However, yesterday I decided to just try a very shallow pass (10 thou deep) on some mild steel with a 3 insert 1.5in milling head with triangle inserts. The finish I got was amazing... Mirror like with rainbow reflection...

So my question is, is anyone using large cutters (anything above an inch - bonus points for single edge cutters) successfully on this mill? One has to take the headstock off the column to check the condition of the two speed gear. Until it strips completely one will not know anything is wrong. So I'm starting this thread to find out if it is something people do on this mill, or am I pushing it beyond the limit?

The answer may be "stick to 10 thou or no deeper cuts", but it is easier said than done. With unsquared work there may be unevenness that means one dials in a 10 thou cut, somewhere along the way it becomes a 20 thou cut for a bit. So I would like to hear what other owners of this mill have to say.

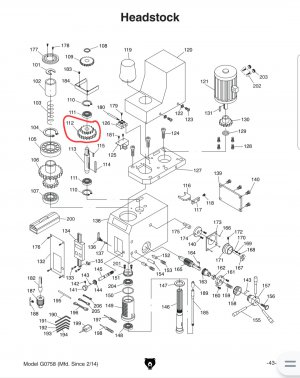

That's the item no 112 here:

I got a new one under warranty, but I had no time to swap it so I kept using the mill on the high gear only. Few years later I replaced this gear finally so now I have low range too. I was firmly decided to never use any flycutters, or any big cutters on that mill.

However, yesterday I decided to just try a very shallow pass (10 thou deep) on some mild steel with a 3 insert 1.5in milling head with triangle inserts. The finish I got was amazing... Mirror like with rainbow reflection...

So my question is, is anyone using large cutters (anything above an inch - bonus points for single edge cutters) successfully on this mill? One has to take the headstock off the column to check the condition of the two speed gear. Until it strips completely one will not know anything is wrong. So I'm starting this thread to find out if it is something people do on this mill, or am I pushing it beyond the limit?

The answer may be "stick to 10 thou or no deeper cuts", but it is easier said than done. With unsquared work there may be unevenness that means one dials in a 10 thou cut, somewhere along the way it becomes a 20 thou cut for a bit. So I would like to hear what other owners of this mill have to say.