- Joined

- Feb 24, 2024

- Messages

- 6

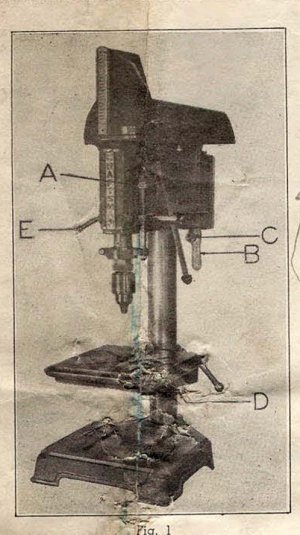

Grandad left me his Atlas 10D lathe with many accessories and an old Sears drill press with a small milling table.

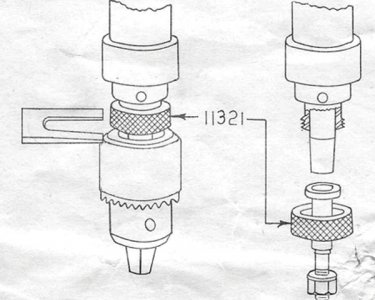

What is this item. The outer diameters are cylindrical and are separated by a ball bearing. The left side has a female #2 Morse taper. The right has the two visible tabs, presumably to drive or be driven by something. Between the drive tabs it's internally threaded, presumably to hold something (a cutter?) onto that end?

What would this be for? Which end would be the driving end? Is it just a leftover piece from something he disassembled? If the tabs hold a cutter, why would the other end have the #2 MT? Could the tabs be on the driving end and be held onto the drill press or Atlas with a screw into the end?

Any thoughts? Thanks!

What is this item. The outer diameters are cylindrical and are separated by a ball bearing. The left side has a female #2 Morse taper. The right has the two visible tabs, presumably to drive or be driven by something. Between the drive tabs it's internally threaded, presumably to hold something (a cutter?) onto that end?

What would this be for? Which end would be the driving end? Is it just a leftover piece from something he disassembled? If the tabs hold a cutter, why would the other end have the #2 MT? Could the tabs be on the driving end and be held onto the drill press or Atlas with a screw into the end?

Any thoughts? Thanks!