- Joined

- Dec 31, 2013

- Messages

- 327

Thought I would show-off my new-to-me SB 10K lathe I picked-up a month or so ago. But first, why I bought it.

For a few years now I've been thinking about getting some machining equipment for my small workshop. With my interest in RC models and model steam, being able to make precise parts has and will come in handy many times. At first I looked at the tiny 7x lathes, but after watching quite a few machinist videos on Youtube (Mr Pete, Doubleboost, Keith Fenner), I realized that a 10" lathe would be much more capable and still fit in the shop if I moved some junk around.

While I'm not totally averse to buying import machinery, after some research I found that China, Inc. doesn't really make a full-featured smaller lathe. For Grizzly, which is local for me, you have to start at the G4002/G4003 line of 12" lathes to get a complete lathe feature set.

Of course, I had been searching CraigsList for almost year and seen alot of rusty, worn-out junk and the few promising deals were usually gone before I got home from work. Just about when I was ready to give-in and drive to the Muncy showroom, this SB dropped into my lap less than an hour away. The seller couldn't have been nicer and the lathe followed me home that morning.

As it turned out that this was a good size lathe for me to buy. With an engine lift I was able to easily get it inside the shop, but quite a few times I only had a few inches to spare one way or the other. I like having equipment that I can move myself as I hope to have a bigger and better shop one day. The underdrive feature is great space saver for a small shop as well.

And here it is in place.

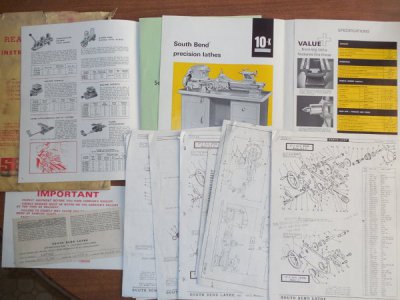

It's a South Bend 10K with a 4 1/2 foot bed. It's a KKX model, which means it's a light 10 with a QC gearbox and underdrive motor. The X in this case means hardened ways, which is a very nice feature to find. It was manufactured in 9/74.

It was manufactured in 9/74.

The lathe came with a very clean and tight Bison 3-jaw chuck. Got a collet hand wheel and holder with 25 of the machine-specific 6K collets. Also included was a "project" Logan 4 jaw chuck that needs the correct backing plate installed, a carriage stop and the usual odds and ends.

Since I bought the lathe I managed to find a SB steady rest and a cheap QCTP as the lantern tool post got old quickly.

Being an older machine I'm sure there's some problems, but having the lathe for a month now I don't see anything major. Got Steve Brook's excellent "Guide to Renovating the South Bend Lathe" and at some time in the future I'll do a complete tear down/rebuild. Not this year, though, as I'm having too much fun using it.

For a few years now I've been thinking about getting some machining equipment for my small workshop. With my interest in RC models and model steam, being able to make precise parts has and will come in handy many times. At first I looked at the tiny 7x lathes, but after watching quite a few machinist videos on Youtube (Mr Pete, Doubleboost, Keith Fenner), I realized that a 10" lathe would be much more capable and still fit in the shop if I moved some junk around.

While I'm not totally averse to buying import machinery, after some research I found that China, Inc. doesn't really make a full-featured smaller lathe. For Grizzly, which is local for me, you have to start at the G4002/G4003 line of 12" lathes to get a complete lathe feature set.

Of course, I had been searching CraigsList for almost year and seen alot of rusty, worn-out junk and the few promising deals were usually gone before I got home from work. Just about when I was ready to give-in and drive to the Muncy showroom, this SB dropped into my lap less than an hour away. The seller couldn't have been nicer and the lathe followed me home that morning.

As it turned out that this was a good size lathe for me to buy. With an engine lift I was able to easily get it inside the shop, but quite a few times I only had a few inches to spare one way or the other. I like having equipment that I can move myself as I hope to have a bigger and better shop one day. The underdrive feature is great space saver for a small shop as well.

And here it is in place.

It's a South Bend 10K with a 4 1/2 foot bed. It's a KKX model, which means it's a light 10 with a QC gearbox and underdrive motor. The X in this case means hardened ways, which is a very nice feature to find.

The lathe came with a very clean and tight Bison 3-jaw chuck. Got a collet hand wheel and holder with 25 of the machine-specific 6K collets. Also included was a "project" Logan 4 jaw chuck that needs the correct backing plate installed, a carriage stop and the usual odds and ends.

Since I bought the lathe I managed to find a SB steady rest and a cheap QCTP as the lantern tool post got old quickly.

Being an older machine I'm sure there's some problems, but having the lathe for a month now I don't see anything major. Got Steve Brook's excellent "Guide to Renovating the South Bend Lathe" and at some time in the future I'll do a complete tear down/rebuild. Not this year, though, as I'm having too much fun using it.