-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

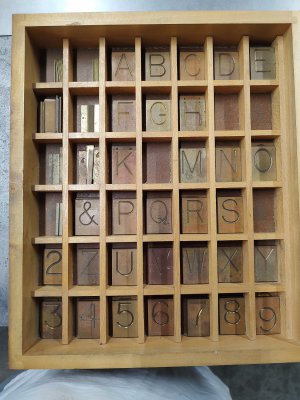

Gorton P1-2 Pantograph Fonts

- Thread starter Arcstar*

- Start date

- Joined

- Dec 6, 2012

- Messages

- 2,677

I also have a P1-2.

Some people might suggest it just takes up floor space.

I've used it her for 4 projects since Nov 1 2023.

Is huge fun! However, there is a significant learning curve, well there was for me. Your mileage may be different.

Sorry no extra fonts.

Daryl

MN

Some people might suggest it just takes up floor space.

I've used it her for 4 projects since Nov 1 2023.

Is huge fun! However, there is a significant learning curve, well there was for me. Your mileage may be different.

Sorry no extra fonts.

Daryl

MN

Thanks Daryl,I also have a P1-2.

Some people might suggest it just takes up floor space.

I've used it her for 4 projects since Nov 1 2023.

Is huge fun! However, there is a significant learning curve, well there was for me. Your mileage may be different.

Sorry no extra fonts.

Daryl

MN

Yeah I've done a couple of projects already and two more in the wings.

I've been able to get by with the incomplete font set I have but really need at least one complete set.

- Joined

- Dec 6, 2012

- Messages

- 2,677

Do you have one of each letter?

You can copy letters at a 1:1 ratio to expand the count.

Which letters do you need, from which set?

If I have a matching set I could make you several letters, if my sets happen to match your gaps.

Shearing the brass and beveling the edges gets problematic. But it's all doable.

Daryl

You can copy letters at a 1:1 ratio to expand the count.

Which letters do you need, from which set?

If I have a matching set I could make you several letters, if my sets happen to match your gaps.

Shearing the brass and beveling the edges gets problematic. But it's all doable.

Daryl

- Joined

- Dec 6, 2012

- Messages

- 2,677

I’ve got a 3U and some fonts. They are the brass ones with angles so they slip right in to the slot, if they are the same I might be able to send you some if I have duplicates.

The letters fit the same.

The angles and bevels make it difficult to copy. But is doable.

Daryl

Do you have one of each letter?

You can copy letters at a 1:1 ratio to expand the count.

Which letters do you need, from which set?

If I have a matching set I could make you several letters, if my sets happen to match your gaps.

Shearing the brass and beveling the edges gets problematic. But it's all doable.

Daryl

I'm missing the I,J,L and T also missing the #1.

I don't want to impose and ask you make any though.

My plan was to 3d print some and transfer over 1:1 on brass strips like you described. I can see how shearing them would warp and bend. I was thinking about rough cutting them on the band saw then cleaning them up with a endmill or slitting saw. Then milling the angle which I think is 20°.