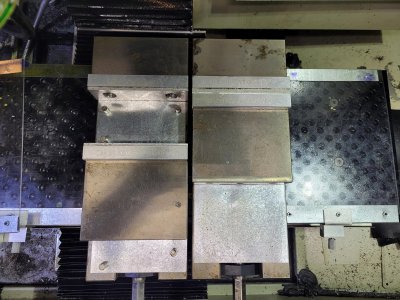

I wanted a mill vise for my new knee mill and I wanted it ASAP and for less than 700 bucks. I looked at orange (too expensive but nice) Kurt (100% of my (excellent) experience) GMT, and a few others. I also wanted a vise that can be used on its side, and will take industry standard Kurt jaws, etc. GMT promised 2 tenths accuracy (not sure what that meant exactly) and also could deliver in a day, I normally would have automatically gon with the Kurt, but liked the lower cost and speed, so GMT was a sweet spot. USA vs Asian was a good thing too.

I took some flatness and straightness measurements and will post a video of that soon. I appreciated another member posting a video of mill stiffness measurements with an indicator, so I figure I’ll let the indicator do the talking.

If u don’t want to watch the vid, Suffice it to say that the flatness and straightness surfaces that are important to me were within the 2 tenths (0.0002”) advertised.

In summary, (my impression) every bit as nice as the many Kurt vises I’ve used, arguably better, but I’m sure Kurt has upped their game in the last 7 years since, so probably not fair to say better than a new Kurt since that is not my experience.

I also looked as the Haas, which seems like a really nice vise, similar price. I have one of their shell mills, which is priced nicely, and is an animal. So darn good value there, and also excellent fit, finish, and performance. The best she’ll mill I have used.

So if anyone is looking g for a 6” mill vise, Haas may be a place to look.

I took some flatness and straightness measurements and will post a video of that soon. I appreciated another member posting a video of mill stiffness measurements with an indicator, so I figure I’ll let the indicator do the talking.

If u don’t want to watch the vid, Suffice it to say that the flatness and straightness surfaces that are important to me were within the 2 tenths (0.0002”) advertised.

In summary, (my impression) every bit as nice as the many Kurt vises I’ve used, arguably better, but I’m sure Kurt has upped their game in the last 7 years since, so probably not fair to say better than a new Kurt since that is not my experience.

I also looked as the Haas, which seems like a really nice vise, similar price. I have one of their shell mills, which is priced nicely, and is an animal. So darn good value there, and also excellent fit, finish, and performance. The best she’ll mill I have used.

So if anyone is looking g for a 6” mill vise, Haas may be a place to look.

Last edited: