- Joined

- Mar 26, 2014

- Messages

- 1,503

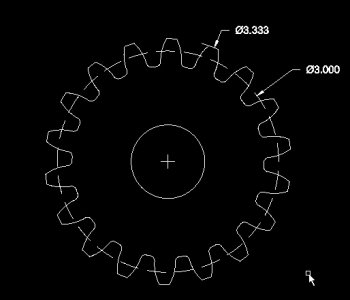

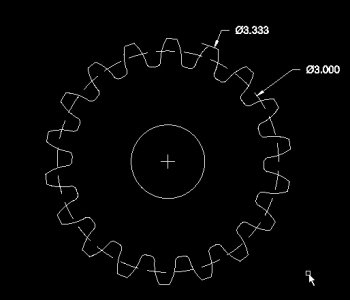

I am making a spur gear for a friend for a 100 year old sausage maker/ meat grinder. I thought it would be fun and gain experience, as I have never cut a gear before. An old guy I know says you don't cut a gear you hob one. I have seen videos of hobbing but I think I will just start out by cutting one on the mill and dividing head.

My gear will have to have a pitch diameter of 3.250" and 18 teeth. I want to order a cutter. I figure I need a #6 cutter? Some cutters from the Ukraine and USSR and China are # 3. They also have a 22mm dia. bore. There are a couple of Butterfield cutters on Ebay that are reasonably priced.

Has anyone ordered a China or USSR cutter before? Are they cheap because of cheap materials? I can make a 22mm arbor.

Are all gears 14.5 degree pitch? I have seen 20 degree cutters also?

Thanks

Martin W

My gear will have to have a pitch diameter of 3.250" and 18 teeth. I want to order a cutter. I figure I need a #6 cutter? Some cutters from the Ukraine and USSR and China are # 3. They also have a 22mm dia. bore. There are a couple of Butterfield cutters on Ebay that are reasonably priced.

Has anyone ordered a China or USSR cutter before? Are they cheap because of cheap materials? I can make a 22mm arbor.

Are all gears 14.5 degree pitch? I have seen 20 degree cutters also?

Thanks

Martin W