- Joined

- Dec 23, 2019

- Messages

- 1,138

OK, this should work:

You have these options:

Doesn't matter which you choose, but you might find some don't fit within size/clearance/banjo constraints.

To explain:

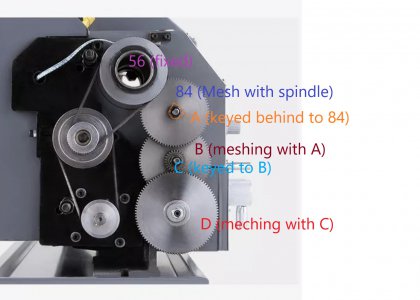

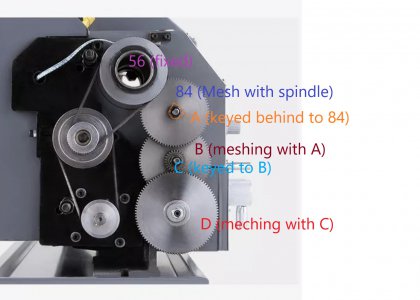

84/56 is 1.5. This is a nice neat ratio. So mesh the 84 with the 56 on the spindle. The spindle will turn 1.5 times for every time the 84 gear makes a complete rotation.

Now, to calculate. This might seem a little roundabout, but bear with me.... There's no way to tell the calculators online (either the LMS or one I posted) that we've got a fixed pair of gears ahead of what it's going to calculate. Essentially, whatever we put downstream of that 56/84 wil turn 1.5 times fewer times than the calculator is expecting. But we can fool it by lying to it about the pitch of the leadscrew to compensate for that 1.5 ratio. A leadscrew that moves 1.5 times less than a 2mm screw for every rotation is 3mm. Nice and easy So bung that into the calc with everything as normal, but telling it you have a 3mm leadscrew and the table above pops out.

So bung that into the calc with everything as normal, but telling it you have a 3mm leadscrew and the table above pops out.

If you don't get it immediately, it doesn't matter. It'll work for any pitch you want, just keep that 84 tooth in that position and tell the calc you've got a 3mm pitch leadcrew.

I *could* have stuffed up some maths somewhere and bozo'd it, but I think that's right. Set the lathe up and see what you get. I like using a sharpie marker in the tool holder when playing with stuff like this. You can't get an exact 16tpi with the gears you have, but the calc shows those options to be within about 0.2%

Keep us posted!!

You have these options:

| A | B | C | D |

| 50 | 80 | 56 | 66 |

| 56 | 80 | 50 | 66 |

| 50 | 66 | 56 | 80 |

| 56 | 66 | 50 | 80 |

Doesn't matter which you choose, but you might find some don't fit within size/clearance/banjo constraints.

To explain:

84/56 is 1.5. This is a nice neat ratio. So mesh the 84 with the 56 on the spindle. The spindle will turn 1.5 times for every time the 84 gear makes a complete rotation.

Now, to calculate. This might seem a little roundabout, but bear with me.... There's no way to tell the calculators online (either the LMS or one I posted) that we've got a fixed pair of gears ahead of what it's going to calculate. Essentially, whatever we put downstream of that 56/84 wil turn 1.5 times fewer times than the calculator is expecting. But we can fool it by lying to it about the pitch of the leadscrew to compensate for that 1.5 ratio. A leadscrew that moves 1.5 times less than a 2mm screw for every rotation is 3mm. Nice and easy

If you don't get it immediately, it doesn't matter. It'll work for any pitch you want, just keep that 84 tooth in that position and tell the calc you've got a 3mm pitch leadcrew.

I *could* have stuffed up some maths somewhere and bozo'd it, but I think that's right. Set the lathe up and see what you get. I like using a sharpie marker in the tool holder when playing with stuff like this. You can't get an exact 16tpi with the gears you have, but the calc shows those options to be within about 0.2%

Keep us posted!!

Last edited: