As the title indicates, the speed lever is difficult to shift to the outer two speeds. The range lever (H/L) is fine. The inner two speeds are a little stiff, but rotate the chuck a little and everything drops in place. Getting in the outer two gears is not impossible but I don't want to break the shift components.

It's slightly easier when I'm in high range, but still a bit sticky. I can feel the shift lever rod and yoke flexing, and the gears don't 'drop' in to place. I simply can't get in the outer gears while in low range without exceeding my "I'm about to break something" tolerance.

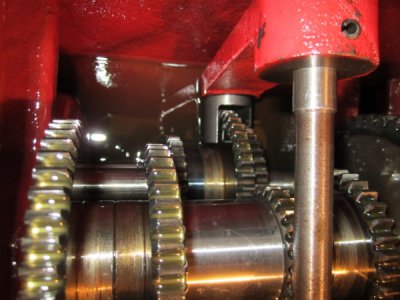

Note - this isn't a problem with the gears meshing. Those are fine and there doesn't appear to be too much or too little gear clearance.

Top cover off revealed no obvious problems. The yoke moves freely through the slack/gap before it tries to shift the input shaft gears. Drive key is seated - double checked with a brass drift and a light tap-tap-tap didn't get it to seat in the keyway any further.

No obvious scoring of the shaft. Drive belt tension isn't too tight so I can't imagine how the shaft would get bent. Oil still clean and full.

So, to sum - the input shaft gears are very difficult to slide to the extreme left and right positions, and a little difficult in the middle two.

Any ideas? Any adjustments I don't know about? Put a dial indicator on the shaft and rotate to see if it's bent or buggered?

Thanks,

Spumco

It's slightly easier when I'm in high range, but still a bit sticky. I can feel the shift lever rod and yoke flexing, and the gears don't 'drop' in to place. I simply can't get in the outer gears while in low range without exceeding my "I'm about to break something" tolerance.

Note - this isn't a problem with the gears meshing. Those are fine and there doesn't appear to be too much or too little gear clearance.

Top cover off revealed no obvious problems. The yoke moves freely through the slack/gap before it tries to shift the input shaft gears. Drive key is seated - double checked with a brass drift and a light tap-tap-tap didn't get it to seat in the keyway any further.

No obvious scoring of the shaft. Drive belt tension isn't too tight so I can't imagine how the shaft would get bent. Oil still clean and full.

So, to sum - the input shaft gears are very difficult to slide to the extreme left and right positions, and a little difficult in the middle two.

Any ideas? Any adjustments I don't know about? Put a dial indicator on the shaft and rotate to see if it's bent or buggered?

Thanks,

Spumco