- Joined

- Jun 2, 2022

- Messages

- 23

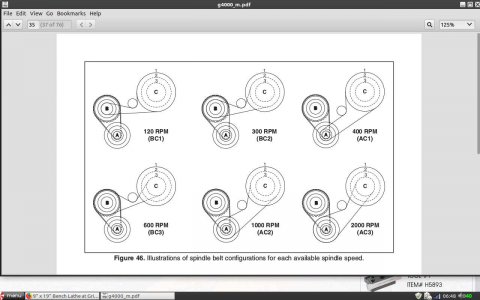

I picked up a used G4000 lathe as my first lathe for learning. The belt that came with it will only install on a couple of different speed pulley combos. Unable to use the belt for the larger slower speed pulleys. Particularly now because I have a steel round I’m trying to turn and the chuck is spinning too fast; not getting a decent finish at all like I have on a couple of aluminum test turns.

Ordered some replacement belts based on the size stated in the manual but they are the same size as the belt that came with it. The belt that came with had no size markings.

Does anyone know if this machine requires 2 different belt sizes? Is there a detail I’m missing to make the state belt size work for all speeds? The Grizzly manual doesn’t reference that 2 belts are required to access all the speeds.

Thanks!

Sent from my iPhone using Tapatalk

Ordered some replacement belts based on the size stated in the manual but they are the same size as the belt that came with it. The belt that came with had no size markings.

Does anyone know if this machine requires 2 different belt sizes? Is there a detail I’m missing to make the state belt size work for all speeds? The Grizzly manual doesn’t reference that 2 belts are required to access all the speeds.

Thanks!

Sent from my iPhone using Tapatalk