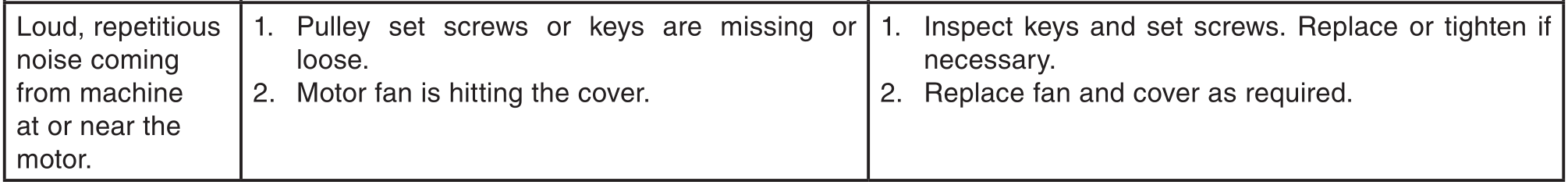

I didn't get the AX33 belt mounted properly (it ended up too slack after running) and the belt didn't seem to be the problem anyway. Since I had to, at a minimum, adjust slack again, I reomved the belt, and determined that it was definitely coming from the motor. Spinning the motor by hand, I could tell that it always clicked at the same motor shaft angle. Oh no, bad bearings, I wept to myself.

I resigned myself to being without a lathe for a while and removed the motor.

This was terrible.

The motor is mounted to a cast iron mount which itself is mounted to the headstock case. The motor is screwed to the mount with 4 14mm hex M8x35 bolts. These, it turned out, were a little loose, which may have explained my difficulty getting the belt tightened properly. I couldn't reach the heads to remove the motor from the mount, only the bolts securing the mount to the headstock.

No problem, I hear you saying.

Almost all the wires from the control box were routed between the motor as the motor mount, so that if I just removed the motor mount, it would tear out the wires. I think it took me somewhere between half an hour and 45 minutes to remove the motor from the lathe. I also removed the motor mount, and discovered that all the wires could be routed between the motor mount and the lathe, so that if I have to remove the motor again in the future, I don't have to do this dance.

As the first step, I removed the fan shroud so I could see what hardware under it I was going to have to remove to tear the motor apart to find the right bearings to order.

The circlip to hold the fan on was not in its retaining groove. It was further in the shaft.

Then I looked at the fan blades. One of these things was not like the other:

Not only, that, but the base of the fan was warped and was running against the motor casing for part of the rotation.

You can see that it even took off a little paint there!

I put the circlip into the groove on the shaft, used a pry bar to push the fan out against the properly positioned circlip, and the motor quit making that annoying noise.

I ground down some M8x30 SCS to 26.5mm, so that they would be the same 25mm long after stacking a 1.5mm M8 washer (unnecessarily, it turned out; M8x30 would have been fine), and ground down the short end of a hex key so that it could fit between the motor and the cap. In retrospect, I could have kept the M8 hex nuts and just used those, since I no longer need to loosen it while the motor is on the lathe. But I didn't think of that at the time.

Then re-mounting the motor, I just pushed the wires into place under the motor mount. There was plenty of room, and it looked like where the wires were intended to run. Now the next time I have to take off the motor, I won't have to worry about those wires. Just disconnect the motor wires and motor and lift it off.

I had two mishaps reassembling it, both electrical. The electrical box had one wire taped up with electrical tape, so someone had already been in there (or maybe it was inexpertly worked at the factory; this is a possibility. In any case, one of the terminals disintegrated while I was lightly tightening the screw, so it was probably already damaged. I wrapped the now-bare connector, still electrically solid, in electrical tape and kept going. But then, I completely forgot that this thing has capacitors, and hadn't tried to discharge them with a resistor or chicken stick, and I re-learned that capacitors can keep their charge for a long time the hard way. ☹

I went back to the original belt to confirm that it had nothing to do with the problem, and in fact it is running in both directions now without that annoying clicking. I had previously heard a very light clicking and thought it was just normal for this lathe. But now it doesn't make that noise at all.

So as far as I can tell, this was a factory defect that just took a long time to turn into a scary noise.

When I compared the two kinds of belts in my hands, they certainly seemed to be the same length. So I'll keep the AX33 belts around for when the current belts fail, especially if the True-Power V13 x 890 belts don't come back into stock.

Anyway, problem solved!

I resigned myself to being without a lathe for a while and removed the motor.

This was terrible.

The motor is mounted to a cast iron mount which itself is mounted to the headstock case. The motor is screwed to the mount with 4 14mm hex M8x35 bolts. These, it turned out, were a little loose, which may have explained my difficulty getting the belt tightened properly. I couldn't reach the heads to remove the motor from the mount, only the bolts securing the mount to the headstock.

No problem, I hear you saying.

Almost all the wires from the control box were routed between the motor as the motor mount, so that if I just removed the motor mount, it would tear out the wires. I think it took me somewhere between half an hour and 45 minutes to remove the motor from the lathe. I also removed the motor mount, and discovered that all the wires could be routed between the motor mount and the lathe, so that if I have to remove the motor again in the future, I don't have to do this dance.

As the first step, I removed the fan shroud so I could see what hardware under it I was going to have to remove to tear the motor apart to find the right bearings to order.

The circlip to hold the fan on was not in its retaining groove. It was further in the shaft.

Then I looked at the fan blades. One of these things was not like the other:

Not only, that, but the base of the fan was warped and was running against the motor casing for part of the rotation.

You can see that it even took off a little paint there!

I put the circlip into the groove on the shaft, used a pry bar to push the fan out against the properly positioned circlip, and the motor quit making that annoying noise.

I ground down some M8x30 SCS to 26.5mm, so that they would be the same 25mm long after stacking a 1.5mm M8 washer (unnecessarily, it turned out; M8x30 would have been fine), and ground down the short end of a hex key so that it could fit between the motor and the cap. In retrospect, I could have kept the M8 hex nuts and just used those, since I no longer need to loosen it while the motor is on the lathe. But I didn't think of that at the time.

Then re-mounting the motor, I just pushed the wires into place under the motor mount. There was plenty of room, and it looked like where the wires were intended to run. Now the next time I have to take off the motor, I won't have to worry about those wires. Just disconnect the motor wires and motor and lift it off.

I had two mishaps reassembling it, both electrical. The electrical box had one wire taped up with electrical tape, so someone had already been in there (or maybe it was inexpertly worked at the factory; this is a possibility. In any case, one of the terminals disintegrated while I was lightly tightening the screw, so it was probably already damaged. I wrapped the now-bare connector, still electrically solid, in electrical tape and kept going. But then, I completely forgot that this thing has capacitors, and hadn't tried to discharge them with a resistor or chicken stick, and I re-learned that capacitors can keep their charge for a long time the hard way. ☹

I went back to the original belt to confirm that it had nothing to do with the problem, and in fact it is running in both directions now without that annoying clicking. I had previously heard a very light clicking and thought it was just normal for this lathe. But now it doesn't make that noise at all.

So as far as I can tell, this was a factory defect that just took a long time to turn into a scary noise.

When I compared the two kinds of belts in my hands, they certainly seemed to be the same length. So I'll keep the AX33 belts around for when the current belts fail, especially if the True-Power V13 x 890 belts don't come back into stock.

Anyway, problem solved!