-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G0704 windshield wiper power feed project - need ideas for cluthc/coupler

- Thread starter jmx66

- Start date

B

British Steel

Forum Guest

Register Today

From one bodger to another...

Mill the motor spindle to 1/2" square, slip on a deep socket, on the feedscrew one short nut to lock, one long (coupling?) nut for the socket to slide over to engage?

Dave H. (the other one)

Mill the motor spindle to 1/2" square, slip on a deep socket, on the feedscrew one short nut to lock, one long (coupling?) nut for the socket to slide over to engage?

Dave H. (the other one)

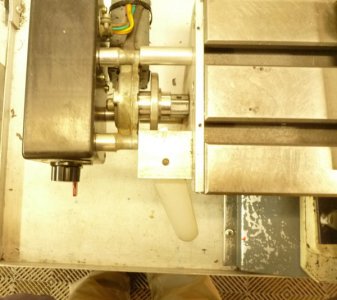

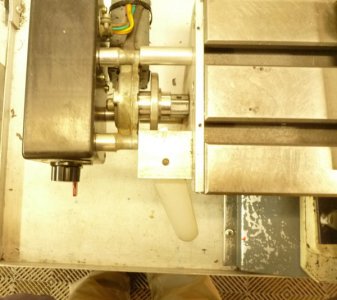

Some progress, sort of.

I milled the wiper arm that attaches to the shaft into a 21mm hex and sacrificed the hand wheel because I didn't want make something to replace it.

So here's where I am.

Staring at it and waiting for a good idea...

I milled the wiper arm that attaches to the shaft into a 21mm hex and sacrificed the hand wheel because I didn't want make something to replace it.

So here's where I am.

Staring at it and waiting for a good idea...

Thanks KD. Some good stuff in that video!I may be going for a more red-neck solution than Lee.

I think for now I've settled on a solution.

I turned down the hand wheel to 20mm and decided against the nut/socket in favor of a 12mm to 20mm 66mm long flexible coupling (thanks Martin) that I'll just loosen with the set screw when I need to go manual.

The motor has three speeds and with the speed control I got, I'll be able to go from barely turning to faster than I'll ever use. So I don't know how often I'll want to go manual.

I also have stop/limit switches that I'm going to attach to the front slot somehow.

No progress until the coupler arrives from China.

I think for now I've settled on a solution.

I turned down the hand wheel to 20mm and decided against the nut/socket in favor of a 12mm to 20mm 66mm long flexible coupling (thanks Martin) that I'll just loosen with the set screw when I need to go manual.

The motor has three speeds and with the speed control I got, I'll be able to go from barely turning to faster than I'll ever use. So I don't know how often I'll want to go manual.

I also have stop/limit switches that I'm going to attach to the front slot somehow.

No progress until the coupler arrives from China.

- Joined

- Feb 26, 2014

- Messages

- 255

I used a 12pt deep socket for my power feed. The motor has a 12t gear and a 3/4" socket fit perfectly. I took some 3/4" hex stock and pined it to the lead screw, cut the square drive from the socket, pressed a disc onto the middle of the socket and used that to manipulate the socket back and forth. I made a quick and dirty nylon forked lever to shift the socket. The gear on the motor has a small stub sticking out and I bored a hole in the one side of the hex stock to engage the stub to keep everything aligned.

- Joined

- Nov 26, 2012

- Messages

- 1,307

For a power knee lift that is internal in my bridgeport knee I used a 24 volt pull solenoid to shift the gearbox of a 1/2 inch cordless drill. I didn't need the high speed side so I ground the gear teeth off on that side and that became neutral. A spring pulls it to the neutral side.

When the power is on for the motor to run the solenoid pulls the gearbox into gear and I can raise and lower the knee with a reversing switch. If I need to move the knee manually it can be done when the power supply is switched off.

It would take some doing but one of those little gearboxes could be installed between your motor and shaft.

When the power is on for the motor to run the solenoid pulls the gearbox into gear and I can raise and lower the knee with a reversing switch. If I need to move the knee manually it can be done when the power supply is switched off.

It would take some doing but one of those little gearboxes could be installed between your motor and shaft.

- Joined

- Feb 1, 2015

- Messages

- 9,605

I think that you will want to go to manual whenever you are positioning to a gnat's eyebrow. Sneaking up on that last half thousandth with a power feed will be tricky. If you overshoot, you will have to back up to remove the lash and have another go it. Changing from power feed to manual feed by loosening a set screw will get old really fast.