- Joined

- Jun 26, 2013

- Messages

- 191

Hi all,

My G0704 mill just has this tiny little stub sticking out of the spindle for tighting/loosening the spindle drawbar:

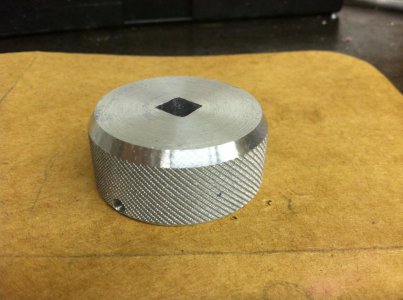

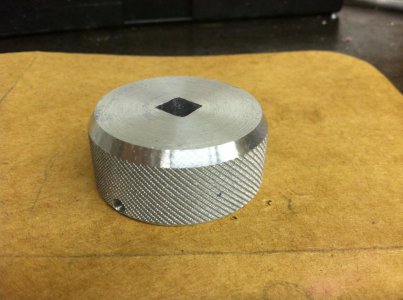

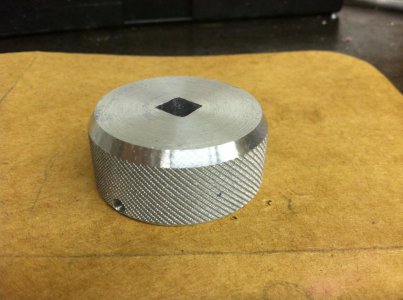

Since I find myself changing tools very often and that tiny little stub hurts my fingers, I decided to make a larger nut/wrench for the end of it:

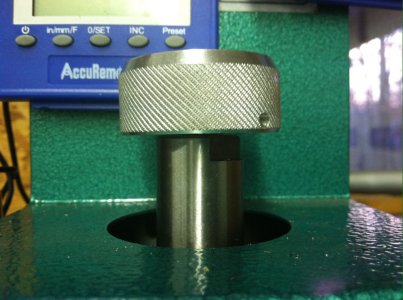

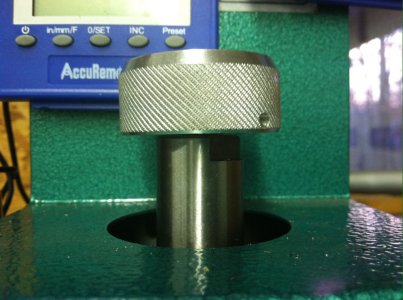

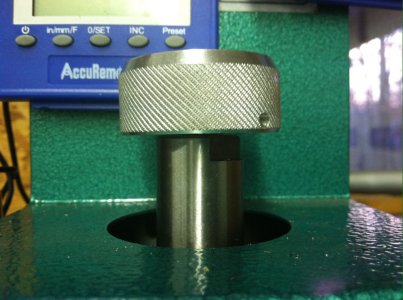

My initial testing tells me that this nut is large (and grippy) enough that I'll be able to use it (in place of the 8mm wrench) to tighten and release tooling, so I want to "permanently" mount it. Since that square hole was finished with a file, it's not perfect a perfect fit for the little stub. It's close, but not perfect. I thought I could use set screws on two adjacent sides to keep the nut snug on the end of the shaft. It does work to keep it on, but when I tighten the set screws the nut "lifts" on that side. You might be able to see the unlevelness in this picture:

This leaves the nut at an angle which causes a very visible (and slightly disconcerting) wobble when the machine is running.

Does anyone have any suggestions on how to avoid the lifting I'm seeing when I snug down the set screws? I was thinking maybe try drilling a couple of indents into the stub for the set screws to settle into - but I'm not sure that's the best approach.

Thanks in advance for any pointers...

My G0704 mill just has this tiny little stub sticking out of the spindle for tighting/loosening the spindle drawbar:

Since I find myself changing tools very often and that tiny little stub hurts my fingers, I decided to make a larger nut/wrench for the end of it:

My initial testing tells me that this nut is large (and grippy) enough that I'll be able to use it (in place of the 8mm wrench) to tighten and release tooling, so I want to "permanently" mount it. Since that square hole was finished with a file, it's not perfect a perfect fit for the little stub. It's close, but not perfect. I thought I could use set screws on two adjacent sides to keep the nut snug on the end of the shaft. It does work to keep it on, but when I tighten the set screws the nut "lifts" on that side. You might be able to see the unlevelness in this picture:

This leaves the nut at an angle which causes a very visible (and slightly disconcerting) wobble when the machine is running.

Does anyone have any suggestions on how to avoid the lifting I'm seeing when I snug down the set screws? I was thinking maybe try drilling a couple of indents into the stub for the set screws to settle into - but I'm not sure that's the best approach.

Thanks in advance for any pointers...