I am making some progress on my 16" Industrial G & E. Lubrication system is operational as is the horizontal table feed and rapids.

I have 2 questions regarding proper settings

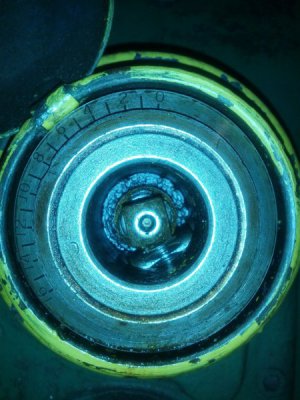

The manual says to change the length of the stroke, stop the shaper so that the "0" is at the top, then use the square hole crank handle to adjust the length.

I've read that there is a lock/brake that automatically releases when the crank is applied to the shaft. The lock is not releasing, is there a trick? No trick, just soak with some penetrating oil for a few days, put the trans in low gear to keep it from spinning and apply some pressure. There doesn't seem to be any type of lock or latch keeping the length to the amount set.

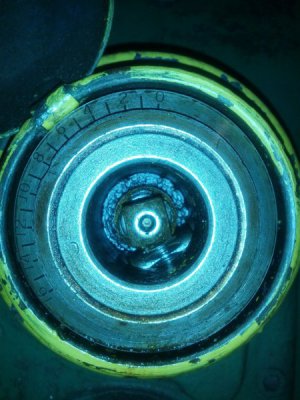

This is a 8 speed machine, I believe it is in "Low gear" and I can switch between the 4 slower stroke speeds, the High/Low lever appears to be frozen (on edit, I wasn't very clear what my question is. I am referring to putting and taking it out of BACKGEAR). Does it need to be pushed down to change from L to H? In it's present setting there is about 1/2" of clean shaft showing. It might have been "down" when the machine was last porch painted.

thanks,

Mike

I have 2 questions regarding proper settings

The manual says to change the length of the stroke, stop the shaper so that the "0" is at the top, then use the square hole crank handle to adjust the length.

I've read that there is a lock/brake that automatically releases when the crank is applied to the shaft. The lock is not releasing, is there a trick? No trick, just soak with some penetrating oil for a few days, put the trans in low gear to keep it from spinning and apply some pressure. There doesn't seem to be any type of lock or latch keeping the length to the amount set.

This is a 8 speed machine, I believe it is in "Low gear" and I can switch between the 4 slower stroke speeds, the High/Low lever appears to be frozen (on edit, I wasn't very clear what my question is. I am referring to putting and taking it out of BACKGEAR). Does it need to be pushed down to change from L to H? In it's present setting there is about 1/2" of clean shaft showing. It might have been "down" when the machine was last porch painted.

thanks,

Mike

Last edited: