- Joined

- Sep 19, 2014

- Messages

- 234

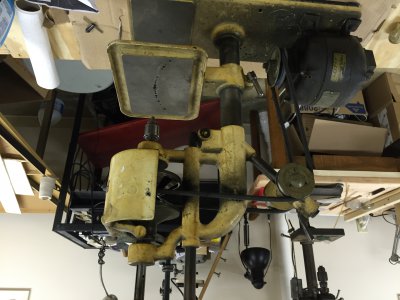

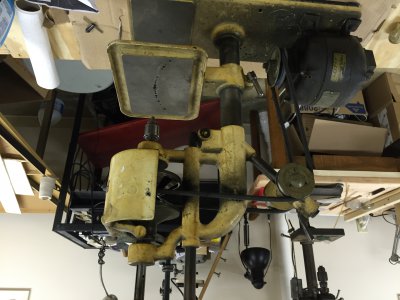

EA few weeks ago I picked up a Victor drill press, small but what I've been looking for, with a 1/4 chuck for $100.

It's in sound shape overall, came with an ugly paint job and a Burke casting for a base as well as some speed holes in the table.

I was tempted to strip and paint it but I'll save that for the future. I'll clean it up, lube it, repair the table, replace the belt, and get it in service.

If any one has more info than vintage machinery has I'd love to here it.

It's in sound shape overall, came with an ugly paint job and a Burke casting for a base as well as some speed holes in the table.

I was tempted to strip and paint it but I'll save that for the future. I'll clean it up, lube it, repair the table, replace the belt, and get it in service.

If any one has more info than vintage machinery has I'd love to here it.