Hi all,

I'm having problems flycutting.

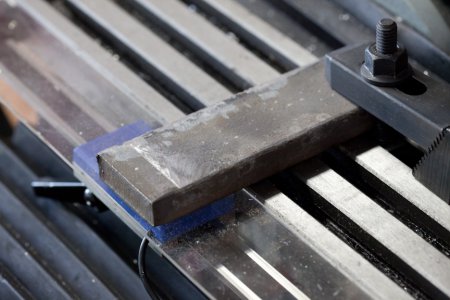

I'm trying to put a finish on some HRS (I think) I got at a scrapyard just for practice.

I have an X2 mini mill I bought from Little Machine Shop about 4 years ago.

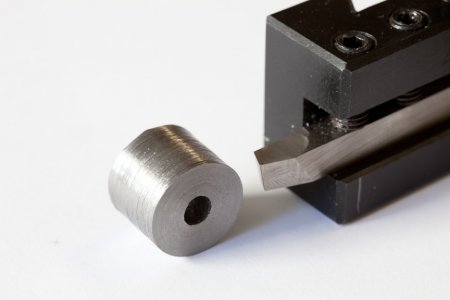

I have a flycutter with an R8 shank.

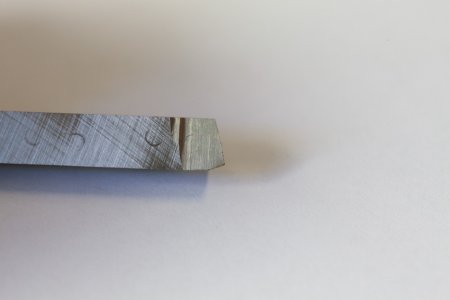

I cut a left hand cutter out of 5/16 HSS blank. Really, all I did was cut a relief angle on the bottom so it wouldn't rub.

What is happening is the cutter is getting ground down by the workpiece instead of the workpiece being cut by the cutter.

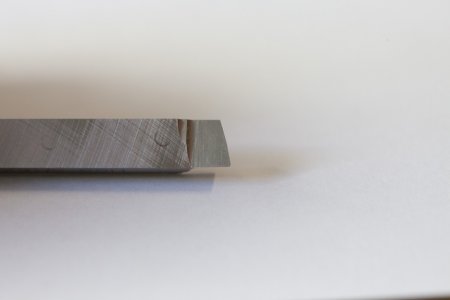

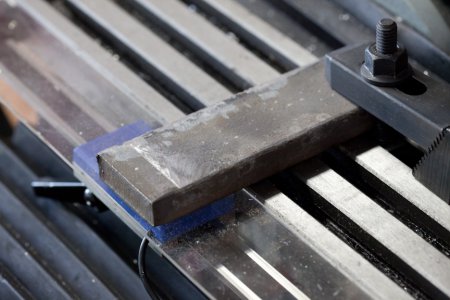

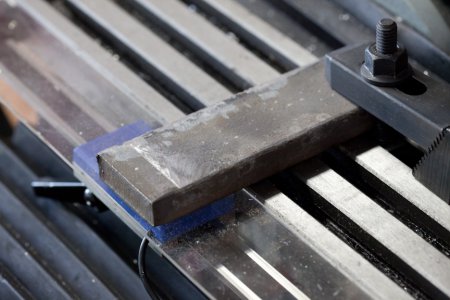

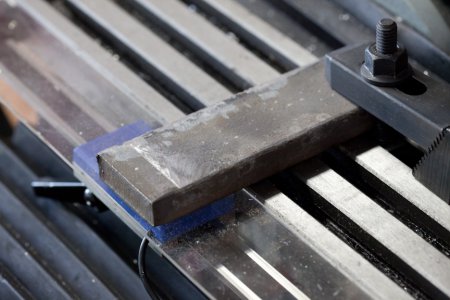

As you can see from the pics, the corner has been shaved off of the cutter, and minimal cutting was done to the steel bar.

I'm using a fairly low speed.

What gives? Any ideas as to what I'm doing wrong?

Thanks,

Darren

I'm having problems flycutting.

I'm trying to put a finish on some HRS (I think) I got at a scrapyard just for practice.

I have an X2 mini mill I bought from Little Machine Shop about 4 years ago.

I have a flycutter with an R8 shank.

I cut a left hand cutter out of 5/16 HSS blank. Really, all I did was cut a relief angle on the bottom so it wouldn't rub.

What is happening is the cutter is getting ground down by the workpiece instead of the workpiece being cut by the cutter.

As you can see from the pics, the corner has been shaved off of the cutter, and minimal cutting was done to the steel bar.

I'm using a fairly low speed.

What gives? Any ideas as to what I'm doing wrong?

Thanks,

Darren

Last edited: