- Joined

- May 13, 2019

- Messages

- 1,016

I see there are a lot of other fly cutter threads going on at the moment, but I don't want to hijack them. So, I'll post a new one here. (Hope this it the right thing to do!)

In any case, I bought a fly cutter (with HSS bit) with a R8 shank from Micro-Mark that I have just started to use on my PM-25MV mill. I'm trying to to determine the proper RPM for this. I know I don't want to go too high since it's not balanced like an end mill.

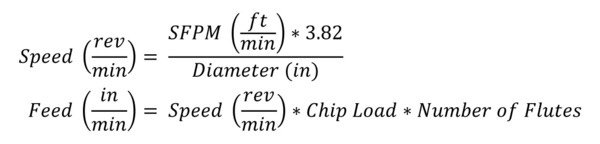

I see a lot of equations for determining RPMs based on SFM and diameter such as: RPM = SFM X 3.82 / D. But, on a manual mill, how do I determine SFM?

Thanks.

In any case, I bought a fly cutter (with HSS bit) with a R8 shank from Micro-Mark that I have just started to use on my PM-25MV mill. I'm trying to to determine the proper RPM for this. I know I don't want to go too high since it's not balanced like an end mill.

I see a lot of equations for determining RPMs based on SFM and diameter such as: RPM = SFM X 3.82 / D. But, on a manual mill, how do I determine SFM?

Thanks.