A

Alan H.

Forum Guest

Register Today

I am tired of hot chips in my face and shoes when turning harder materials like high strength steel. With input from some friends, I chose a Flexbar Model 13061 for installation on my PM1340GT. I like the Flexbar solution since it is easily removable or it will store in the up position. This model is a good fit for the PM1340. It appears that the replacement Lexan is readily available.

I played with various mounting schemes, dimensions, and positions. I used a wood mounting plate for a trial on the chosen position before I went to the trouble of fabricating the mounting plate. I wanted the adjustment/removal knob to be easy to get to; the center of the guard's arc to be aligned with centerline of the chuck; and not to be forced to relocate the light.

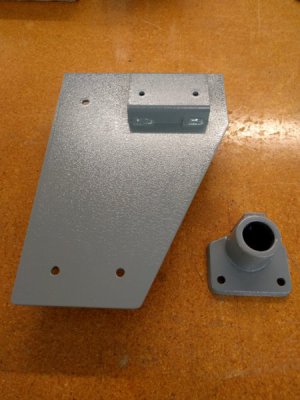

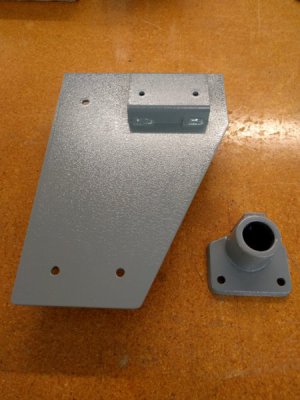

Here are the parts for the mounting plate. The material is nominal 1/8” thick steel. I split a piece of tubing to extend the mount to the plane of the lathe backsplash. The split tubing bracket was milled to the final thickness needed.

Here is the bracket welded, painted and ready for installation. I finished it with a hammered finish since it will get scratched up quickly. The backsplash sheet metal protrusion at the mounting point didn't allow for a flat mount, so the bracket was made to extend to that plane.

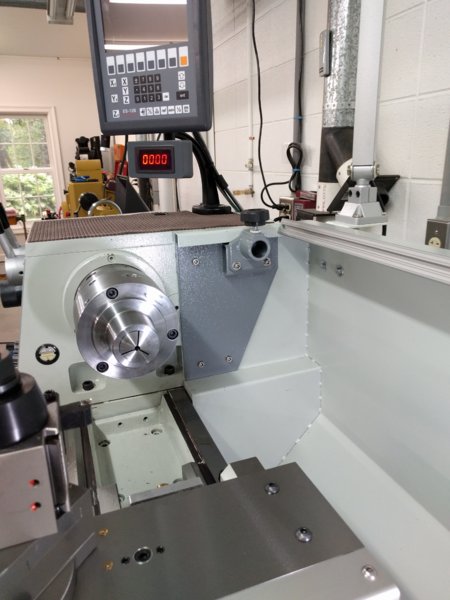

Here’s the bracket in place on the lathe. The position of the adjusting/removal knob landed where I wanted it to for easy access. The existing backsplash bolting was used to attach the plate.

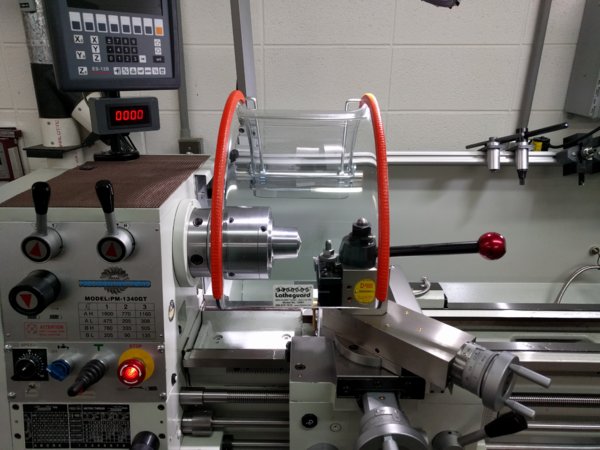

In place and down:

It tilts up out of the way and with this spacing it is very stable if you forget to tighten the adjusting knob. This also accommodates leaving the light in its factory mounting position.

I realize many folks prefer to not have one of these in the way and I understand. But it will be a nice safety feature to have when I want and need the added protection from a chuck and/or chips. With this arrangement it is easy enough to tilt it up or take it off when I feel that it is not needed.

Thanks David and Mark for your help.

I played with various mounting schemes, dimensions, and positions. I used a wood mounting plate for a trial on the chosen position before I went to the trouble of fabricating the mounting plate. I wanted the adjustment/removal knob to be easy to get to; the center of the guard's arc to be aligned with centerline of the chuck; and not to be forced to relocate the light.

Here are the parts for the mounting plate. The material is nominal 1/8” thick steel. I split a piece of tubing to extend the mount to the plane of the lathe backsplash. The split tubing bracket was milled to the final thickness needed.

Here is the bracket welded, painted and ready for installation. I finished it with a hammered finish since it will get scratched up quickly. The backsplash sheet metal protrusion at the mounting point didn't allow for a flat mount, so the bracket was made to extend to that plane.

Here’s the bracket in place on the lathe. The position of the adjusting/removal knob landed where I wanted it to for easy access. The existing backsplash bolting was used to attach the plate.

In place and down:

It tilts up out of the way and with this spacing it is very stable if you forget to tighten the adjusting knob. This also accommodates leaving the light in its factory mounting position.

I realize many folks prefer to not have one of these in the way and I understand. But it will be a nice safety feature to have when I want and need the added protection from a chuck and/or chips. With this arrangement it is easy enough to tilt it up or take it off when I feel that it is not needed.

Thanks David and Mark for your help.