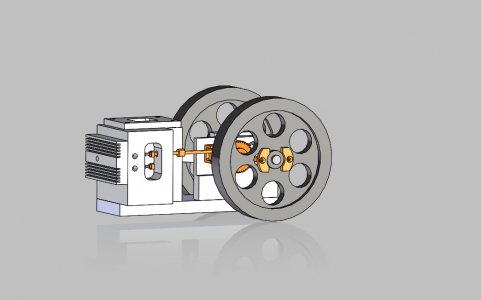

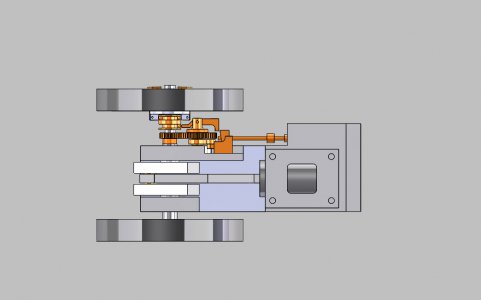

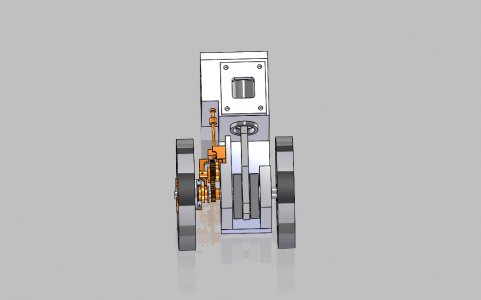

After the success I had with the white gas in the other hit miss engine I built I have decided to build a flat head hit miss engine similar to the one that Ray built a while ago. I looked thru the different hit miss engine builds that Ray did and I liked the flat head design. The valves are not sticking out the top of the head and you do not need a rocker arm and rocker arm mount for the exhaust valve. Below are the design specifications.

1" bore

1.5" throw

Ball Bearings to support the crank shaft

6:1 compression ratio

6" diameter flywheels

David Kerzel style governor (like I used for my previous motor)

Unlike Ray I need to do the design and drawings first then start machining. Once I get the layout done I will post some photos of the layout. I will be doing the design in SolidWorks that I have for work.

Ray, if you see something in the design specs that you think will cause problems feel free to let me know. I am a novice at the engine design.

Thanks

Roger L

1" bore

1.5" throw

Ball Bearings to support the crank shaft

6:1 compression ratio

6" diameter flywheels

David Kerzel style governor (like I used for my previous motor)

Unlike Ray I need to do the design and drawings first then start machining. Once I get the layout done I will post some photos of the layout. I will be doing the design in SolidWorks that I have for work.

Ray, if you see something in the design specs that you think will cause problems feel free to let me know. I am a novice at the engine design.

Thanks

Roger L