Tried and failed . thanks for the comment. Bwhy couldn't you use your old account?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Most is on U tube look at brian hogger 5 cylinder radial or THORWelcome Back!

Can't wait to see pictures.

Later i will post the link B

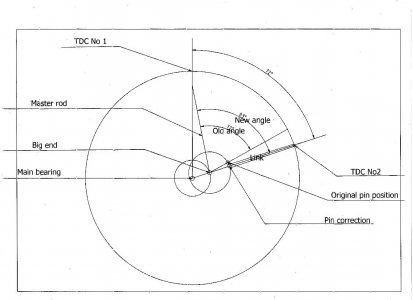

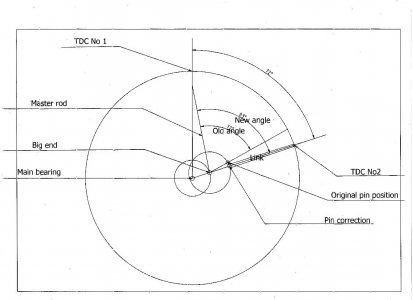

OK when I left this forum we where about to make the Master rod ( you can refer to post #274 for a ghosted front view of the engine) This

rod is the only one connected directly to a piston the remaining piston's are attached to the master rod by slave/ link. rods,

This causes a problem because the slave is not fitted directly to the big end and the master rocks from side to side causing the other piston's to not get to TDC at72° intervals. To correct this the connection points on the Master rod are moved to compensate.

Brian

rod is the only one connected directly to a piston the remaining piston's are attached to the master rod by slave/ link. rods,

This causes a problem because the slave is not fitted directly to the big end and the master rocks from side to side causing the other piston's to not get to TDC at72° intervals. To correct this the connection points on the Master rod are moved to compensate.

Brian

- Joined

- Apr 29, 2019

- Messages

- 2,060

It is all in the geometry

When the crank has turned 72° the crank pin on the crank shaft will be aligned for TDC on the next cylinder. BUT in the process of that rotation the crank end of the main con rod has rotated to still be aligned with the wrist pin in the top cylinder. The offset is to make up for the amount that the big end of the main rod has moved.

When the crank has turned 72° the crank pin on the crank shaft will be aligned for TDC on the next cylinder. BUT in the process of that rotation the crank end of the main con rod has rotated to still be aligned with the wrist pin in the top cylinder. The offset is to make up for the amount that the big end of the main rod has moved.

If you look at the drawing the main bearing - big end- and link pin must all be in line at 72°to get the piston to TDC, The rock back of the master rod stops this from happening so we reposition the pin for each of the other cylinders. The problem with this is that the link has high angularity

half way down the stroke and it can foul the bottom of the cylinder. Mine ran it very close on cylinders 3and4, Making the cylinders- master rod -and links longer helps but I was committed having made everything.

half way down the stroke and it can foul the bottom of the cylinder. Mine ran it very close on cylinders 3and4, Making the cylinders- master rod -and links longer helps but I was committed having made everything.

- Joined

- Mar 25, 2013

- Messages

- 4,616

I understand now. Because the master rod does not have a joint at cylinder #1, that causes some CW and CCW rotation of the entire master rod. You need to account for this rotation in determining the correct angle for TDC for the other cylinders.