-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

First Turning Tool Holder Set

- Thread starter Kroll

- Start date

- Joined

- Dec 11, 2014

- Messages

- 891

Don't know much about either one, but the first set will have 3 different inserts to buy to replace them.

The second set are all the same type of insert, so you can buy a box of 10 and be good for quite a while.

I have a set I got free that looks something like the second one and like it for general turning and facing.

I already had the replacement inserts for it and the only reason I took it.

The second set are all the same type of insert, so you can buy a box of 10 and be good for quite a while.

I have a set I got free that looks something like the second one and like it for general turning and facing.

I already had the replacement inserts for it and the only reason I took it.

Thanks,that what I notice also.Just wanted to keep it simple.Buy inserts that for steel,aluminum and stainless steel.Mike I will be using these on my Colchester which I just got a piece of mild steel in that's 10" long so that I can get started on the headstock checking the alignment this weekend.

- Joined

- Sep 29, 2014

- Messages

- 2,102

Buying "sets" is pointless without knowing what the work is going to be, buy tools for the job at hand.

In the first picture the far right tool is a trigon insert, WNMT, an excellent roughing tool that will both turn and face equally well.

The third one from the left looks like a 55 Deg. insert tool, VNMG these are excellent for turning close to a center, fragile however due to the sharp angles.

Laydown threading tools work fine but may also interfere with a center when turning small threads, vertical thread tools will get much closer.

Buy only the tools that you NEED and will WORK for the job, before long you will have so many tools that you will start a thread called "insert storage advice".

In the first picture the far right tool is a trigon insert, WNMT, an excellent roughing tool that will both turn and face equally well.

The third one from the left looks like a 55 Deg. insert tool, VNMG these are excellent for turning close to a center, fragile however due to the sharp angles.

Laydown threading tools work fine but may also interfere with a center when turning small threads, vertical thread tools will get much closer.

Buy only the tools that you NEED and will WORK for the job, before long you will have so many tools that you will start a thread called "insert storage advice".

- Joined

- Apr 23, 2013

- Messages

- 1,004

The first set gives you a cut off tool , a threading tool , and left and right hand turning tools and a profile turning tool. Set uses 5 different inserts that are double sided the thread insert will probably not cut deep course threads. But it is a good start for a home shop. I bought a set and think foe the price you cannot go wrong.

Set comes with starter inserts. One Kennametal insert tool and 10 pack of inserts is

more costly then the set.

jimsehr

Set comes with starter inserts. One Kennametal insert tool and 10 pack of inserts is

more costly then the set.

jimsehr

When I went to busybee knowing nothing about using a lathe, and something like set #2 was recommended for me. After busting all the tips of one of them, I switched to hand-ground (well, using a grinder with a special wheel) high-speed steel tooling and haven't looked back. For learning, it is much more forgiving than using carbide inserts. At least, it was for me.

I use some glued on carbide that I resharpen (1-2 at a time usually), two pieces of HSS, some center drills, jobber drills, broken drills, & on rare occasion a bore bar. That I believe is about the limit for cutting tools on my lathe. I did run into needing to cut a internal thread that was really tinny & I had to grind a really small piece of HSS round that was such a pain in the but I decided to order a bar with carbide insert for the next time. I don't think I've used it since.

ETA:I forgot about my saw blade I use for parting. That is rare that I part in the lathe. I usually cut work to length before chucking it up when I can.

ETA:I forgot about my saw blade I use for parting. That is rare that I part in the lathe. I usually cut work to length before chucking it up when I can.

- Joined

- Nov 23, 2014

- Messages

- 2,606

I'm a self-taught hobbyist which translates to I make LOTS of mistakes, so take anything I advise with a bag of sand, not a grain.

I have 3 or 4 of the 5-piece set in your second picture, the RH one (second one over from the left) is my "go to" turning/facing tool. My first two sets came with regular Allen wrench metric screws - absolutely HATEd them. Very easy to round out the screws (or me over-torquing?). I think I bought the 3rd set from Shars or CDCO which came with metric torx head screws - huge improvement. I bought extra screws from Shars and replaced all of the Allen head with torx head. I don't know if the sets you're looking at have torx or allen, but if they're from Shars they probably have the torx bits. I don't think I've ever used the two intermediate tools, just the center, LH and RH.

There are lots of posts here regarding problems with parting. The first tool set gives you a grooving/cut-off tool which as mentioned above, if mounted securely in a QCTP, it will greatly ease parting. It also gives you an external threading tool, and probably all the turning tools you'd ever use. The set looks like part# 404-1052 or 1053 (1/2" or 5/8") from Shars for around $100.

The second set will require you to buy a number of different inserts: MGMN300 (parting/grooving), 16 ER AG60 (external threading) and WCMX 25.1 or .2, CCMT 21.5 and DCMT 21.5 for the turning/facing tools. By the way, I wouldn't buy the inserts from Shars unless you need them right away. You can shop on eBay and get the MGMN300 bits for under $12 for 10, but you'll have to wait a month to get them from China. Same for the other inserts, they are typically $25 or less for 10 of them from China.

Between the two sets (and since I'm spending you money . . .) I'd go with the second set of tool holders. You'll want to pick up a set of boring bars too.

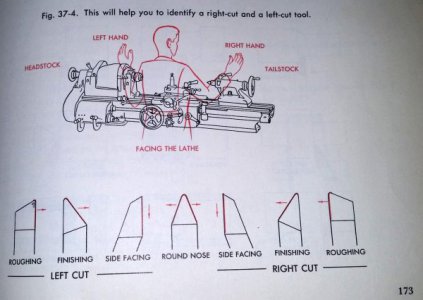

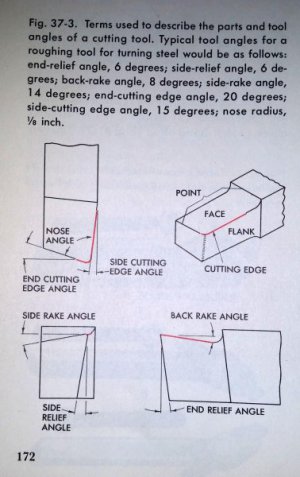

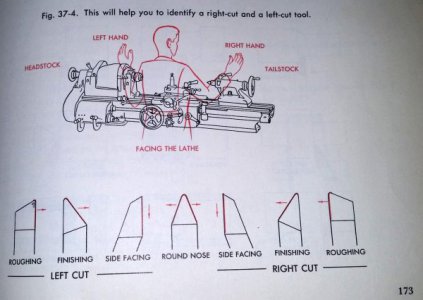

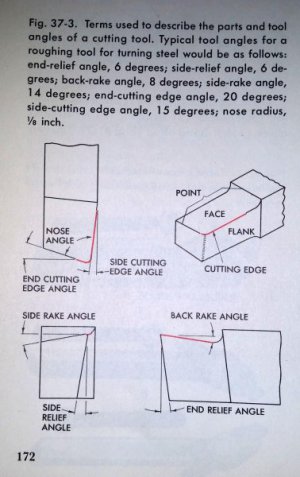

That all being said, my dad was a high school shop teacher. I used to tag along with him after hours and in the summer when he worked in the shop making teaching aids, fixing equipment, etc. I recall "helping" him make visual aids for students out of 2 x 2's for grinding high speed steel. I painted the ground surfaces and stenciled on the angles and use of the bits. There's are pictures below of the text book pages showing HSS tools used in the shop. My dad taught 100's of students how to grind HSS and turn with HSS. Their high school shop never had any inserts in it. Didn't have any QCTP's either, just lantern style tool posts on Clausing 5400 and 5900 series lathes. Parting was usually done on a band saw since the lantern-style parting tools are extremely frustrating to use because of their lack of rigidity.

WOW, finally a summary. . . The carbide inserts are great for instant gratification and ease of use. You should learn at some point how to grind HSS bits, you never know when you'll have an odd ball job that requires a specially ground tool.

By the way, I believe the recommended turning speeds are doubled when you go with carbide over HSS. Google "Tom's Techniques" and watch Tom Griffin's videos on turning speeds; he's an excellent teacher. He recommends turning speeds of 400 divided by the work/tool diameter for steel which has worked well for me. That translates to 800 RPM's if turning a 1/2" steel round or drilling steel with a 1/2" drill bit/end mill ( 400 / .5). For carbide, the corresponding speeds would be 1600 RPM's.

Have fun tooling up, always fun to spend money on your shop!

Bruce

I have 3 or 4 of the 5-piece set in your second picture, the RH one (second one over from the left) is my "go to" turning/facing tool. My first two sets came with regular Allen wrench metric screws - absolutely HATEd them. Very easy to round out the screws (or me over-torquing?). I think I bought the 3rd set from Shars or CDCO which came with metric torx head screws - huge improvement. I bought extra screws from Shars and replaced all of the Allen head with torx head. I don't know if the sets you're looking at have torx or allen, but if they're from Shars they probably have the torx bits. I don't think I've ever used the two intermediate tools, just the center, LH and RH.

There are lots of posts here regarding problems with parting. The first tool set gives you a grooving/cut-off tool which as mentioned above, if mounted securely in a QCTP, it will greatly ease parting. It also gives you an external threading tool, and probably all the turning tools you'd ever use. The set looks like part# 404-1052 or 1053 (1/2" or 5/8") from Shars for around $100.

The second set will require you to buy a number of different inserts: MGMN300 (parting/grooving), 16 ER AG60 (external threading) and WCMX 25.1 or .2, CCMT 21.5 and DCMT 21.5 for the turning/facing tools. By the way, I wouldn't buy the inserts from Shars unless you need them right away. You can shop on eBay and get the MGMN300 bits for under $12 for 10, but you'll have to wait a month to get them from China. Same for the other inserts, they are typically $25 or less for 10 of them from China.

Between the two sets (and since I'm spending you money . . .) I'd go with the second set of tool holders. You'll want to pick up a set of boring bars too.

That all being said, my dad was a high school shop teacher. I used to tag along with him after hours and in the summer when he worked in the shop making teaching aids, fixing equipment, etc. I recall "helping" him make visual aids for students out of 2 x 2's for grinding high speed steel. I painted the ground surfaces and stenciled on the angles and use of the bits. There's are pictures below of the text book pages showing HSS tools used in the shop. My dad taught 100's of students how to grind HSS and turn with HSS. Their high school shop never had any inserts in it. Didn't have any QCTP's either, just lantern style tool posts on Clausing 5400 and 5900 series lathes. Parting was usually done on a band saw since the lantern-style parting tools are extremely frustrating to use because of their lack of rigidity.

WOW, finally a summary. . . The carbide inserts are great for instant gratification and ease of use. You should learn at some point how to grind HSS bits, you never know when you'll have an odd ball job that requires a specially ground tool.

By the way, I believe the recommended turning speeds are doubled when you go with carbide over HSS. Google "Tom's Techniques" and watch Tom Griffin's videos on turning speeds; he's an excellent teacher. He recommends turning speeds of 400 divided by the work/tool diameter for steel which has worked well for me. That translates to 800 RPM's if turning a 1/2" steel round or drilling steel with a 1/2" drill bit/end mill ( 400 / .5). For carbide, the corresponding speeds would be 1600 RPM's.

Have fun tooling up, always fun to spend money on your shop!

Bruce