Loaded the new mill on my MC lift and moved it over to the stand.

Corrected the Z.

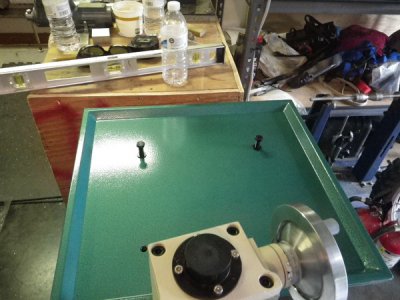

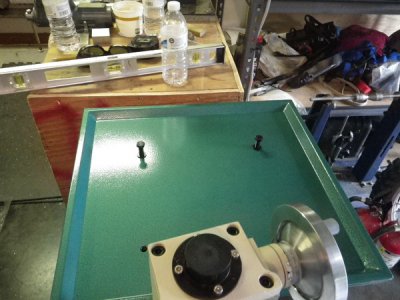

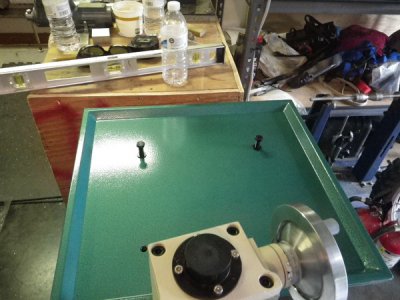

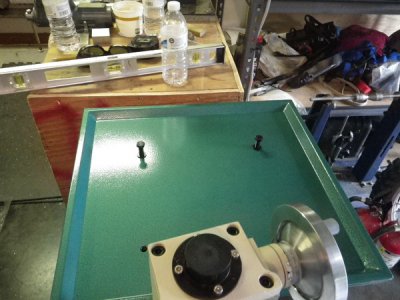

Put two bolts in the pan to keep it from sliding.

Pushed it into place.

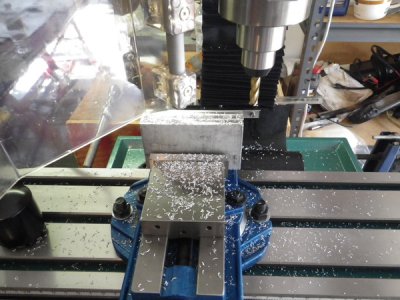

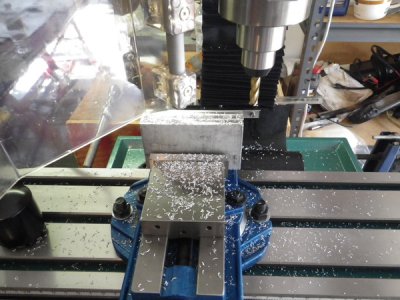

Bolted it down, splashed on some WD-40, completed the bearing run in and made the first chips.

X is off less than 0.001" in 6 inches.

I am happy. Runs smooth, but the motor gets really hot.

All in all it will surpass my present mill needs for some time........then it will knee..d to be something in the 3 phase 10+ x 50+ category.

Corrected the Z.

Put two bolts in the pan to keep it from sliding.

Pushed it into place.

Bolted it down, splashed on some WD-40, completed the bearing run in and made the first chips.

X is off less than 0.001" in 6 inches.

I am happy. Runs smooth, but the motor gets really hot.

All in all it will surpass my present mill needs for some time........then it will knee..d to be something in the 3 phase 10+ x 50+ category.