Hi All

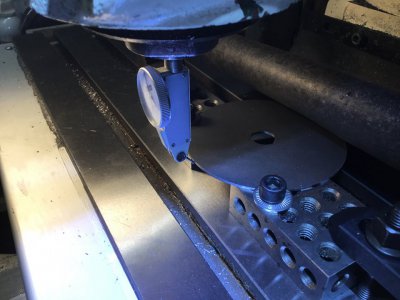

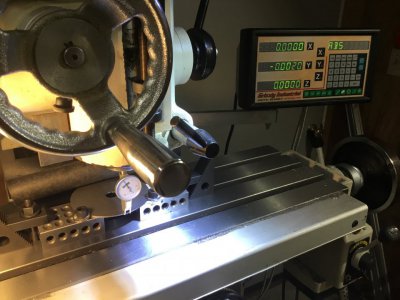

I'm trying to find a quick and accurate way of finding the bottom of a disk that is clamped down on 123 blocks.

The bottom would be that part of the disk closest to the front edge of the mill table. I have some ideas but I'm wondering what you all do.

I'm trying to find a quick and accurate way of finding the bottom of a disk that is clamped down on 123 blocks.

The bottom would be that part of the disk closest to the front edge of the mill table. I have some ideas but I'm wondering what you all do.