- Joined

- Apr 8, 2013

- Messages

- 1,982

I'm just gonna use a lite piece of angle between 2 of the faceplate holes with a slot for the dog. I may have to put the dog backwards.I have the same set of dogs from Grizzly, a very similar faceplate, and the same dilemma. I was thinking of bolting a couple of pieces from a hold-down kit to the faceplate to drive the dogs. Drive the dog with one side and have another on the other side of the faceplate to balance it. Any reason this would not work or be dangerous?

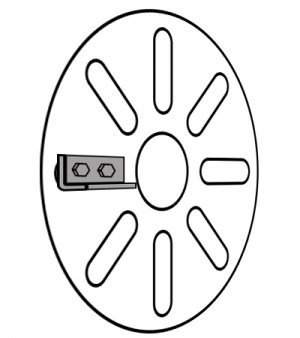

Here is the part I was thinking of using for this:

View attachment 82925