- Joined

- Feb 5, 2015

- Messages

- 662

This review was written several years ago. The criticisms of the distributor that I made at the time may no longer be warranted. I've found that customer service is a hit-or-miss proposition. I've had excellent customer service from small Mom and Pop tooling distributors and very poor service from large, well-known distributors such as the one mentioned in this post.

Most lathe tooling inventories include several 4-jaw chucks of different diameters and they are used often - good workholders and indispensable for many requirements. I'm also very appreciative of scroll chucks if concentricity to existing diameters is not critical, as a matter of convenience. My smallest lathe has neither cam-lock nor threaded spindle and it's time-consuming to change chucks so the normal workholder is a 4 inch, 3-jaw chuck.

I've wanted a 6-jaw scroll chuck for a long time. Good ones are usually superior to 3-jaw and 4-jaw chucks in gripping power and normally superior to 3-jaws in concentricity and repeatability. These devices are hard to find for small lathes like my Emco "Compact Eight". The "set-true" configurations - the most desirable ones - start at 6 inches in diameter, too large for an eight inch lathe.

Imported 4 inch diameter, 6-jaw chucks are available but aren't "set-true" design. Hardened jaws common to most scroll chucks aren't easily modified so that adjustable "soft" jaws can be added. Nevertheless I decided to order and evaluate one of these imports with the eventual idea of modifying the chuck to add adjustable jaws.

Importers provide sparse information about chucks and backplates; it's confusing to mate the two at long distance, ha-ha. The allusion, generally, is that a backplate WILL be required but not much help is provided to select it if one doesn't happen to own a standard configuration spindle. I ordered the chuck without a backplate because there may be advantages:

This is what I actually received:

There are no stepped jaws, which cripples the versatility of this device. One of the main reasons for owning a 6-jaw scroll chuck is the ability to grip - internally - thin tubular workpieces, spreading the load more effectively with less distortion than 3-jaw and 4-jaw workholders. This chuck cannot grip ANY internal features. Additionally, the separate set of external gripping jaws - a standard feature with scroll chucks - wasn't included. The booklet that accompanied the chuck listed the extra jaws as included parts and as we know, jaws in scroll chucks are not reversible, as are those in independent chucks.

Another disadvantage of the "no-step" jaw configuration is that several modifications that I'd envisioned to obtain adjustability are impossible. (While waiting for delivery of the chuck, I'd conceived a couple of schemes for attaching adjustable soft jaws to the stepped jaws with which the chuck was to be equipped.)

Modifying any chuck would be a simple process if the jaws weren't hardened, of course. Although jaws can be annealed, machined and re-hardened there is risk of distortion (perhaps more like a certainty). Finish grinding jaw contours may not be difficult but distortion of the scroll interface might make the chuck near-useless !

That is the problem with any scroll chuck. It's possible to true the jaws of inexpensive chucks very accurately but only at one specific diameter when the adjustment pinions are tightened to a normal torque range. The key to accuracy and concentricity is the scroll and it's hard to imagine a more difficult geometrical configuration to produce in quantities !

The main cost of quality scroll chucks is probably the cost of making a precise scroll. Making these formerly required a universal milling machine with geared dividing head (modern scrolls are made on a CNC mill). I lifted this photo from another forum as an example of machinery once used to produce scrolls (a vertical head, not shown in this photo, is normally attached for this operation):

Another possibility for re-configuring jaws like the ones in the chuck that I received might include plasma cutting to rough shape and then finish grinding but the risk of distortion is still significant. Although possible in theory, the least desirable alternative would be rough-milling the steps with a carbide cutter then grinding to dimension in the lathe.

Although I do occasionally mill hardened steel with solid carbide cutters, the feed rate must be slow and I really wouldn't care to spend a day or two milling six hardened jaws. If I had a wire EDM machine, life would be so very GOOD ! Anyway, so much for the idea of adding "set-true" features to this chuck so let's move on.

From the above photo of the chuck that Grizzly shipped, it can be noted that the tapered jaws are about twice the length of the stepped jaws shown in their ad photo. The extra gripping length would seem to be desirable but the tradeoff is additional overhang. The face of the workpiece would be about twice the distance from the chuck face as my veteran 3-jaw. If the jaws are axially true with the mounting feature then the problem might simply be one of diminished rigidity (more on this later).

When short workpieces are gripped often, long chuck jaws may not be the best workholder. They will "bell-mouth" more rapidly than strong, stubby jaws - not necessarily just from jaw wear but from slight amounts of scroll distortion and keyway wear, multiplied by the distance of the workpiece from the scroll. One might make an argument that the extra gripping power and rigidity of the 6-jaw outweighs this shortcoming - that would be a complicated analysis that I wouldn't care to make.

Speaking of "grip", the jaws on the Grizzly chuck were perfectly smooth. (It's the first chuck I've seen like this except for "commutator chucks", the ones with bronze jaws used specifically as a bearing surface - sort of a steady rest residing in tailstocks of lathes set up for electric motor work.)

Tradition, mostly for good reason, suggests that jaws of workholding chucks (not drill chucks) be serrated to increase holding power and the Grizzly ad photo depicts serrated jaws. It's not a huge drawback, fifteen minutes work with a diamond wheel in a Dremel tool can correct this.

It has been suggested that chucks like these are normally found on T & C grinders and I recall seeing one or two. In a situation where the chuck jaws might be ground to suit a specific application, then there would be no need for serrations that would be ground off anyway.

Of course for operations of this nature (i.e. tool sharpening), one would expect a higher level of precision from the toolholding device, right? The chuck was delivered with a booklet of "operating instructions" and an inspection sheet signed by three different people with the same handwriting. Unhappily, none of the sixteen critical measurements (jaw runout, body runout, face perpendicularity and mounting dimensions) were measured.

Actually, I don't know that they weren't measured I just know that no measurements were recorded on the inspection sheet. The booklet provided was written for a 3-jaw chuck, not a 6-jaw chuck. The model number stamped on the face of the chuck didn't match any of the model numbers described in the booklet. Most of the measurements were related to the various clamping positions of the STEPPED jaws which do not exist on the chuck that I received so any recorded measurements would have been an intentional deception anyway.

I should know by now to calibrate my expectations lower when buying imported products. But where else can we buy some of these tools ? American (and many European) products have disappeared as a result of price-cutting. The result is that quality standards are now established by the seller because an effective monopoly exists. Grizzly, Enco, MSC and even the smaller importers also influence quality standards by pressing manufacturers to design to a specific price goal.

Something has to slip in terms of quality or capability. There is little point in complaining to importers about these "slight" discrepancies. The buyer's reluctance to return goods is factored into their business plan, in my opinion. And to be fair, the importer is somewhat at the mercy of the factories in China …

This is the classic quandary that the HSM purchaser, with little economic leverage, encounters. We purchase machinery with an expectation of performance that is neither guaranteed nor stated - simply implied. After waiting for some time and paying substantial shipping costs, we might unpack a machine, get it into service (sometimes taking several days) and find that the machine doesn't perform to expectation.

What's next? Repack the machine (maybe having to rent or borrow again the hoist or forklift that was used to set it up), pay again for a shipper to pick it up and return it to the importer ? And then pay the importer a re-stocking fee ? This is a perfect storm that benefits only the seller. In this case, the ending wasn't quite so bleak as you'll discover.

One of the biggest bites for home machinists is the difficulty of moving large machinery (or paying double shipping costs) and THAT results in a reluctance to return unsatisfactory products to the importer. This may be a result of moving/rigging inexperience when some decide to make metalworking their hobby. Importers and distributors know this and may take advantage of the fact - this is why I suggest that it is an integral part of their business plan.

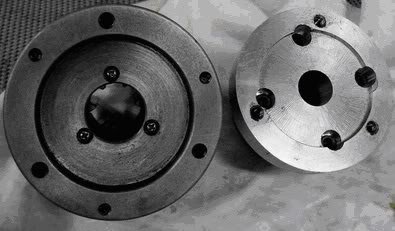

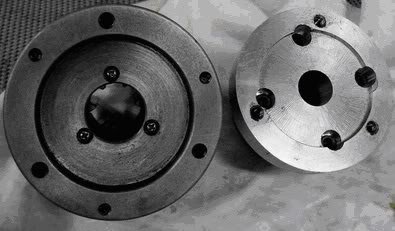

There remained one ray of sunshine in THIS chuck experience, I thought. The booklet that accompanied the Grizzly chuck specified that the mounting dimensions would fit my spindle perfectly, HURRAY. But when I measured the rear of the chuck, I found that the bore diameter was much larger than the lathe spindle spigot, the mounting holes were on a different bolt circle and had different threads. Oh well, the experience so far was consistent - as in BAD. Here is a photo of the back of the 6-jaw, beside it is an old aluminum backplate for a small 4-jaw with the correct dimensions:

At this point, the weekend had arrived and nothing could be done to return the chuck. I decided to spend some time reviewing the product since others might benefit from the additional inspection. I disassembled the chuck for cleaning and inspection, noting that the internal details and workmanship were as good as a Polish-made Bison chuck that I had occasion to take apart a few months ago. There were no chips or foreign debris in the internal mechanism, just the greasy preservative with which the chuck was protected. Although the construction alloys used are obviously unknown the details were FAR better than I had a right to expect for the purchase price.

After re-assembling and engaging all six jaws in the scroll then rotating the adjustment pinions two turns, I measured the largest diameter this chuck could support at 1-1/4 inches. Scrolling the jaws closed, I measured the smallest diameter the chuck could grip at 3/32 inch. Summarizing the major characteristics:

Runout was measured in the lathe by first turning a shaft about ten inches long, true to the spindle axis and the tailstock center. (The shaft was indicated before mounting the 6-jaw, confirming no radial runout.) The shaft diameter was approximately 1/2 inch which is about the center of the chuck adjustment range. After withdrawing the tailstock, the 6-jaw was slipped over the shaft and carefully tightened, one pinion at a time. The tailstock was then re-engaged and tightened.

Measured runout at the mounting bore (and the outside diameter of the chuck) was .0025. The test was repeated three times using different techniques including gripping the end of the shaft with a "known good" 5/8 drill chuck in the tailstock. No runout improvement was noted in any of the setups when compared to the first measurement.

After breaking down the measurement setup, I was curious to see how my original 3-jaw chuck performed compared to this new product. I measured the runout of a 1/2 inch ground drill rod next to the chuck jaws at .0005 inch and at 3 inches from the jaws at .0025 inch. (The drill rod was completely engaged with the full length of the chuck jaws to preclude "bell-mouthing" in the old chuck from affecting runout measurement.)

The booklet enclosed with the 6-jaw chuck specified .003 runout at the same distance from the chuck face. So the new chuck could offer no advantage over the forty-year old 3-jaw except in gripping power and the ability to spread pressure over the workpiece. The old 3-jaw chuck can grip outside diameters from 1/32 to 4 inches and inside diameters from 1-1/2 to 4 inches. Larger diameters than these are limited by the swing over the carriage, not by the chuck.

Returning this tool required approval by Grizzly - I sent three e-mails to Grizzly customer service before receiving a response. A customer service representative telephoned me four days after my initial e-mail. He said that he had requested the warehouse to open one of the product shipping containers and that the tool indeed had the deficiencies noted in my description. The representative asked how quickly I could pack the chuck, I told him that it was packed already. I was given a RMA (returned material authorization) number and told that UPS would pick up the chuck from my house - no shipping charges.

Some two and one-half weeks and two more e-mails later I was still waiting. I received a call from Grizzly, wanting to know if my address was correct. Since they had successfully shipped the chuck to this address and successfully billed me at this address, picking the chuck up from the same address should not have presented a challenge, right ? (An earlier e-mail from the same person implied - without actually stating it - that perhaps nobody was home when "they" tried to pick up the part.)

That seemed to be either an evasion or an attempt to blur responsibility and I responded accordingly. You'd think that importers of Chinese products would have their act together when it comes to returns, since many of their products either get returned or require replacement parts. It took three weeks for the chuck to be picked up but I didn't have to pay return shipping costs, for which I am grateful. Grizzly informed me a few days later that the chuck had been received. My account was credited for the charge several weeks later.

This experience started out optimistically but each successive discovery reminded me of other stories that I've read about customer dissatisfaction with imported products. But what are we to do since there are so few alternatives left to us now ? I hope that this experience might be helpful to someone considering a device like this one. For those who are not concerned about .003 runout, the ability to grip tubing (or bored workpieces) and whose work diameters are within an envelope of around 1/8 to 1-1/4 inches, this is a nice little chuck.

For not very much more money, a collet chuck would do a better job.

Most lathe tooling inventories include several 4-jaw chucks of different diameters and they are used often - good workholders and indispensable for many requirements. I'm also very appreciative of scroll chucks if concentricity to existing diameters is not critical, as a matter of convenience. My smallest lathe has neither cam-lock nor threaded spindle and it's time-consuming to change chucks so the normal workholder is a 4 inch, 3-jaw chuck.

I've wanted a 6-jaw scroll chuck for a long time. Good ones are usually superior to 3-jaw and 4-jaw chucks in gripping power and normally superior to 3-jaws in concentricity and repeatability. These devices are hard to find for small lathes like my Emco "Compact Eight". The "set-true" configurations - the most desirable ones - start at 6 inches in diameter, too large for an eight inch lathe.

Imported 4 inch diameter, 6-jaw chucks are available but aren't "set-true" design. Hardened jaws common to most scroll chucks aren't easily modified so that adjustable "soft" jaws can be added. Nevertheless I decided to order and evaluate one of these imports with the eventual idea of modifying the chuck to add adjustable jaws.

Importers provide sparse information about chucks and backplates; it's confusing to mate the two at long distance, ha-ha. The allusion, generally, is that a backplate WILL be required but not much help is provided to select it if one doesn't happen to own a standard configuration spindle. I ordered the chuck without a backplate because there may be advantages:

- Given a fortunate combination of chuck and spindle dimensions, the chuck can be modified to fit the spindle (with REAL luck it might even fit without modification … this will be discussed again later).

- Modifying the chuck can save money and provide greater accuracy because overhang is reduced and so are the cumulative errors of spindle, backplate and chuck. There are techniques that minimize accumulated inaccuracy but they are ineffective if the scroll of the chuck is not precise - more on this later. The four inch 3-jaw chuck usually mounted on my lathe has no backplate and has given almost forty years of service.

- Blank backplates are expensive. It's possible that one may have a piece of steel plate suitable for making a backplate provided that time is available to do so. In my case a blank backplate would cost about $70 while the material to make one would cost $16. Making a backplate is straightforward work and takes an hour or two.

- Improving chuck performance - for example, by designing and making a configuration that allows adjustment of the chuck to the backplate, allowing "tuning" the chuck for specific diameter ranges.

This is what I actually received:

There are no stepped jaws, which cripples the versatility of this device. One of the main reasons for owning a 6-jaw scroll chuck is the ability to grip - internally - thin tubular workpieces, spreading the load more effectively with less distortion than 3-jaw and 4-jaw workholders. This chuck cannot grip ANY internal features. Additionally, the separate set of external gripping jaws - a standard feature with scroll chucks - wasn't included. The booklet that accompanied the chuck listed the extra jaws as included parts and as we know, jaws in scroll chucks are not reversible, as are those in independent chucks.

Another disadvantage of the "no-step" jaw configuration is that several modifications that I'd envisioned to obtain adjustability are impossible. (While waiting for delivery of the chuck, I'd conceived a couple of schemes for attaching adjustable soft jaws to the stepped jaws with which the chuck was to be equipped.)

Modifying any chuck would be a simple process if the jaws weren't hardened, of course. Although jaws can be annealed, machined and re-hardened there is risk of distortion (perhaps more like a certainty). Finish grinding jaw contours may not be difficult but distortion of the scroll interface might make the chuck near-useless !

That is the problem with any scroll chuck. It's possible to true the jaws of inexpensive chucks very accurately but only at one specific diameter when the adjustment pinions are tightened to a normal torque range. The key to accuracy and concentricity is the scroll and it's hard to imagine a more difficult geometrical configuration to produce in quantities !

The main cost of quality scroll chucks is probably the cost of making a precise scroll. Making these formerly required a universal milling machine with geared dividing head (modern scrolls are made on a CNC mill). I lifted this photo from another forum as an example of machinery once used to produce scrolls (a vertical head, not shown in this photo, is normally attached for this operation):

Another possibility for re-configuring jaws like the ones in the chuck that I received might include plasma cutting to rough shape and then finish grinding but the risk of distortion is still significant. Although possible in theory, the least desirable alternative would be rough-milling the steps with a carbide cutter then grinding to dimension in the lathe.

Although I do occasionally mill hardened steel with solid carbide cutters, the feed rate must be slow and I really wouldn't care to spend a day or two milling six hardened jaws. If I had a wire EDM machine, life would be so very GOOD ! Anyway, so much for the idea of adding "set-true" features to this chuck so let's move on.

From the above photo of the chuck that Grizzly shipped, it can be noted that the tapered jaws are about twice the length of the stepped jaws shown in their ad photo. The extra gripping length would seem to be desirable but the tradeoff is additional overhang. The face of the workpiece would be about twice the distance from the chuck face as my veteran 3-jaw. If the jaws are axially true with the mounting feature then the problem might simply be one of diminished rigidity (more on this later).

When short workpieces are gripped often, long chuck jaws may not be the best workholder. They will "bell-mouth" more rapidly than strong, stubby jaws - not necessarily just from jaw wear but from slight amounts of scroll distortion and keyway wear, multiplied by the distance of the workpiece from the scroll. One might make an argument that the extra gripping power and rigidity of the 6-jaw outweighs this shortcoming - that would be a complicated analysis that I wouldn't care to make.

Speaking of "grip", the jaws on the Grizzly chuck were perfectly smooth. (It's the first chuck I've seen like this except for "commutator chucks", the ones with bronze jaws used specifically as a bearing surface - sort of a steady rest residing in tailstocks of lathes set up for electric motor work.)

Tradition, mostly for good reason, suggests that jaws of workholding chucks (not drill chucks) be serrated to increase holding power and the Grizzly ad photo depicts serrated jaws. It's not a huge drawback, fifteen minutes work with a diamond wheel in a Dremel tool can correct this.

It has been suggested that chucks like these are normally found on T & C grinders and I recall seeing one or two. In a situation where the chuck jaws might be ground to suit a specific application, then there would be no need for serrations that would be ground off anyway.

Of course for operations of this nature (i.e. tool sharpening), one would expect a higher level of precision from the toolholding device, right? The chuck was delivered with a booklet of "operating instructions" and an inspection sheet signed by three different people with the same handwriting. Unhappily, none of the sixteen critical measurements (jaw runout, body runout, face perpendicularity and mounting dimensions) were measured.

Actually, I don't know that they weren't measured I just know that no measurements were recorded on the inspection sheet. The booklet provided was written for a 3-jaw chuck, not a 6-jaw chuck. The model number stamped on the face of the chuck didn't match any of the model numbers described in the booklet. Most of the measurements were related to the various clamping positions of the STEPPED jaws which do not exist on the chuck that I received so any recorded measurements would have been an intentional deception anyway.

I should know by now to calibrate my expectations lower when buying imported products. But where else can we buy some of these tools ? American (and many European) products have disappeared as a result of price-cutting. The result is that quality standards are now established by the seller because an effective monopoly exists. Grizzly, Enco, MSC and even the smaller importers also influence quality standards by pressing manufacturers to design to a specific price goal.

Something has to slip in terms of quality or capability. There is little point in complaining to importers about these "slight" discrepancies. The buyer's reluctance to return goods is factored into their business plan, in my opinion. And to be fair, the importer is somewhat at the mercy of the factories in China …

This is the classic quandary that the HSM purchaser, with little economic leverage, encounters. We purchase machinery with an expectation of performance that is neither guaranteed nor stated - simply implied. After waiting for some time and paying substantial shipping costs, we might unpack a machine, get it into service (sometimes taking several days) and find that the machine doesn't perform to expectation.

What's next? Repack the machine (maybe having to rent or borrow again the hoist or forklift that was used to set it up), pay again for a shipper to pick it up and return it to the importer ? And then pay the importer a re-stocking fee ? This is a perfect storm that benefits only the seller. In this case, the ending wasn't quite so bleak as you'll discover.

One of the biggest bites for home machinists is the difficulty of moving large machinery (or paying double shipping costs) and THAT results in a reluctance to return unsatisfactory products to the importer. This may be a result of moving/rigging inexperience when some decide to make metalworking their hobby. Importers and distributors know this and may take advantage of the fact - this is why I suggest that it is an integral part of their business plan.

There remained one ray of sunshine in THIS chuck experience, I thought. The booklet that accompanied the Grizzly chuck specified that the mounting dimensions would fit my spindle perfectly, HURRAY. But when I measured the rear of the chuck, I found that the bore diameter was much larger than the lathe spindle spigot, the mounting holes were on a different bolt circle and had different threads. Oh well, the experience so far was consistent - as in BAD. Here is a photo of the back of the 6-jaw, beside it is an old aluminum backplate for a small 4-jaw with the correct dimensions:

At this point, the weekend had arrived and nothing could be done to return the chuck. I decided to spend some time reviewing the product since others might benefit from the additional inspection. I disassembled the chuck for cleaning and inspection, noting that the internal details and workmanship were as good as a Polish-made Bison chuck that I had occasion to take apart a few months ago. There were no chips or foreign debris in the internal mechanism, just the greasy preservative with which the chuck was protected. Although the construction alloys used are obviously unknown the details were FAR better than I had a right to expect for the purchase price.

After re-assembling and engaging all six jaws in the scroll then rotating the adjustment pinions two turns, I measured the largest diameter this chuck could support at 1-1/4 inches. Scrolling the jaws closed, I measured the smallest diameter the chuck could grip at 3/32 inch. Summarizing the major characteristics:

- The chuck cannot grip any inside diameter: a pipe, a tube or anything with a bore

- The chuck can ONLY grip outside diameters from 3/32 to 1-1/4 inch

- 5C collets can do anything that this chuck can do and do it better

Runout was measured in the lathe by first turning a shaft about ten inches long, true to the spindle axis and the tailstock center. (The shaft was indicated before mounting the 6-jaw, confirming no radial runout.) The shaft diameter was approximately 1/2 inch which is about the center of the chuck adjustment range. After withdrawing the tailstock, the 6-jaw was slipped over the shaft and carefully tightened, one pinion at a time. The tailstock was then re-engaged and tightened.

Measured runout at the mounting bore (and the outside diameter of the chuck) was .0025. The test was repeated three times using different techniques including gripping the end of the shaft with a "known good" 5/8 drill chuck in the tailstock. No runout improvement was noted in any of the setups when compared to the first measurement.

After breaking down the measurement setup, I was curious to see how my original 3-jaw chuck performed compared to this new product. I measured the runout of a 1/2 inch ground drill rod next to the chuck jaws at .0005 inch and at 3 inches from the jaws at .0025 inch. (The drill rod was completely engaged with the full length of the chuck jaws to preclude "bell-mouthing" in the old chuck from affecting runout measurement.)

The booklet enclosed with the 6-jaw chuck specified .003 runout at the same distance from the chuck face. So the new chuck could offer no advantage over the forty-year old 3-jaw except in gripping power and the ability to spread pressure over the workpiece. The old 3-jaw chuck can grip outside diameters from 1/32 to 4 inches and inside diameters from 1-1/2 to 4 inches. Larger diameters than these are limited by the swing over the carriage, not by the chuck.

Returning this tool required approval by Grizzly - I sent three e-mails to Grizzly customer service before receiving a response. A customer service representative telephoned me four days after my initial e-mail. He said that he had requested the warehouse to open one of the product shipping containers and that the tool indeed had the deficiencies noted in my description. The representative asked how quickly I could pack the chuck, I told him that it was packed already. I was given a RMA (returned material authorization) number and told that UPS would pick up the chuck from my house - no shipping charges.

Some two and one-half weeks and two more e-mails later I was still waiting. I received a call from Grizzly, wanting to know if my address was correct. Since they had successfully shipped the chuck to this address and successfully billed me at this address, picking the chuck up from the same address should not have presented a challenge, right ? (An earlier e-mail from the same person implied - without actually stating it - that perhaps nobody was home when "they" tried to pick up the part.)

That seemed to be either an evasion or an attempt to blur responsibility and I responded accordingly. You'd think that importers of Chinese products would have their act together when it comes to returns, since many of their products either get returned or require replacement parts. It took three weeks for the chuck to be picked up but I didn't have to pay return shipping costs, for which I am grateful. Grizzly informed me a few days later that the chuck had been received. My account was credited for the charge several weeks later.

This experience started out optimistically but each successive discovery reminded me of other stories that I've read about customer dissatisfaction with imported products. But what are we to do since there are so few alternatives left to us now ? I hope that this experience might be helpful to someone considering a device like this one. For those who are not concerned about .003 runout, the ability to grip tubing (or bored workpieces) and whose work diameters are within an envelope of around 1/8 to 1-1/4 inches, this is a nice little chuck.

For not very much more money, a collet chuck would do a better job.