Alright, another interesting day, this time I tackled and finished the 'base'. Usually I would do something like this first, but wasn't convinced right away I had all the necessary dimensions.

First, despite what the plans say (which is not to!), I opted to flatten the feet. I figure it was counting on a single setup in the mill to do the whole top, and I did it in 2 operations. I couldn't get it to sit flat enough on the mill without doing this, but when done, I was perfectly flat:

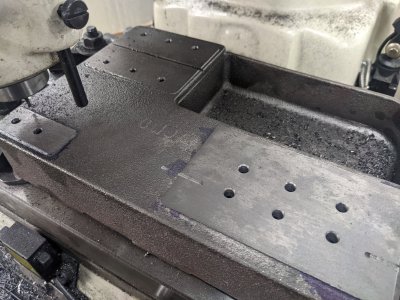

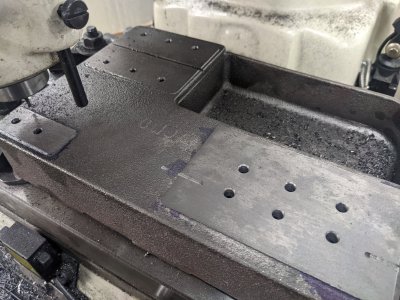

Next, I flipped it over and used a wiggler to find a straight-ish part of the casting flats to set my zeros:

SO the big important thing I figured out is what is the important dimensions. FIRST, there is 3 pads. The hole patterns inside each one are critical, but the dimensions between them are NOT critical, with 1 exception. The MOST critical part is that they are all 'square' to each-other, so it is important to do all the holes/etc in 1 setup.

The ONE important relationship is that the bottom left and top left pads share a left-side 'zero'. Additionally, the dimensions on the top-left (the .750 from the RHS of the flat) ACTUALLY should be relative to the LHS of the flat. THis is because the relationship between the 'EL' piece we made earlier and the hob-holder spindle are important.

I started by drilling/tapping the lower-left, and convinced myself I got it right enough to move on. Then I started the upper left by cutting the groove for the keystock. Plans call for just a piece on each side for this one, but I chose instead to cut it all the way across, so I could use a single piece if I cared to.

Finally, I drilled/tapped the holes in it, and this pad was done!

The lower right went similarly, and centered the stuff on the pad rather than try to make it relative to the other two pads (which wasn't on the plans anyway!).

I drilled the holes (not tapped, the bolts come in from the bottom!), and cut the keyway slot in this one too. Note that I COULDN'T go all the way across, because for some reason the key would go through the 3 bottom mounting holes.

I DID have a minor oopsie on this one as you can see to the left of the left key-stock slot. While raising the table to cut the final cut, I nipped into the top of the casting ~2 thou. I'm hopeful no one here will tell on me once this gets painted

SO, the base is done! I couldn't find my stash of 1/4-20 bolts to pop the two other parts onto this in the meantime, so thats all the pics I have today.

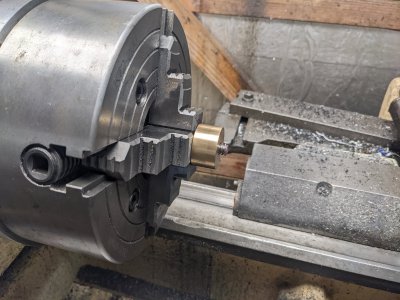

ADDITIONALLY, I started to try to setup for the hob-spindle-holder stuff since my bearings were on their way, but I couldn't get my 6 jaw off the lathe! I suspect that is going to be my next big thing. Mixed with the pass-around-box showing up today, I wasn't going to get anything else done