I don't plan on using most of the plastic cases, unless it's a special cutter or doesn't fit in a sorter box.

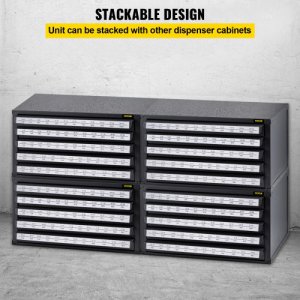

Knowing I was going to have to manage a lot of cutters, taps and drills, I built a 10-drawer add-on tool chest specifically for this project. I got lucky and found a small, cheap Plano sorter box from Menards fits my tool chest drawers well. I ended up buying all they had of this:

View attachment 432231

I like that I'll be able to organize cutters and taps in smaller, separate quantities, and that the boxes stack and have lids.

How to physically store the end mills is not a concern. My original question was, what methodology for organizing do the members of this site use? Does it make sense to separate by diameter, or by # of flutes, or by HSS vs Carbide, High or Std. helix?