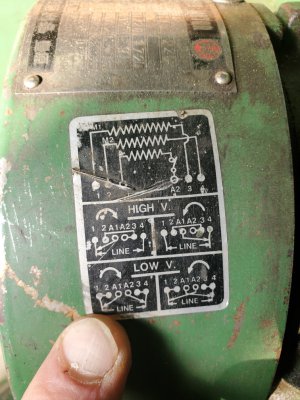

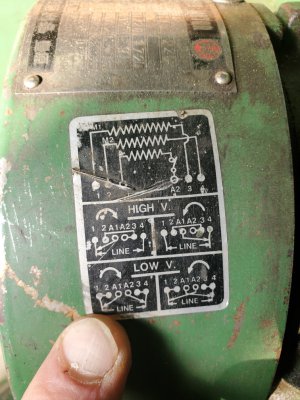

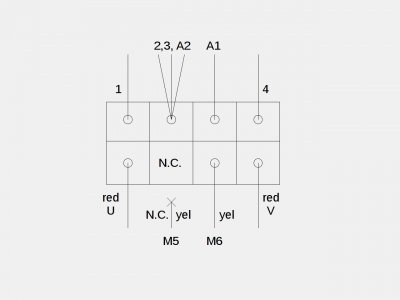

I've perused this forum and the entire internet and have still to find another motor with a schematic like mine. I'm fairly familiar rewiring motors for changes in direction and hookup, but this has me thrown for a loop. Looking to rewire to 220, currently 110 CCW. Does any of this make sense to anyone?