-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ENC VFD on a Lathe

- Thread starter David2011

- Start date

- Joined

- Apr 30, 2015

- Messages

- 11,328

First thing to do is get it working locally without any external switches, then hook up the switches and start

adjusting settings

adjusting settings

It’s working now; struggling to get the default cycles changed from 50 to 60. It’s not critical but the speed on the gearhead ought to match the spindle speed. The roundabout wording is giving me fits. With the Automation Direct VFD once I got the sequence of entries down it was logical and easy and I got through setting every parameter without needing the instructions for changing them again. On the ENC I think I’m following the instructions but it’s hard to know if I’m even on the correct parameter.

Once it’s set to 60hz the ramp up and down speeds need to be changed. A short ramp up is OK and even desirable. Instead of ramping down a full cut and coast to stop would be great. It currently takes several seconds to stop due to the slow ramp down rate.

Gotta assemble new raised gardening beds for my wife to stay out of the doghouse, then back to the VFD.

Once it’s set to 60hz the ramp up and down speeds need to be changed. A short ramp up is OK and even desirable. Instead of ramping down a full cut and coast to stop would be great. It currently takes several seconds to stop due to the slow ramp down rate.

Gotta assemble new raised gardening beds for my wife to stay out of the doghouse, then back to the VFD.

New perspective. After assembling the raised beds and their drawings of parts with no suggested order of assembly, the instructions for the VFD don't seem quite as bad.

After going through the function parameters line by line they aren't so bad. It's the information between Figures 3-6 to 3-11 that left me puzzled. She's taking me to my favorite Mexican restaurant for putting her raised beds together so I'll continue on the VFD later this evening.

After going through the function parameters line by line they aren't so bad. It's the information between Figures 3-6 to 3-11 that left me puzzled. She's taking me to my favorite Mexican restaurant for putting her raised beds together so I'll continue on the VFD later this evening.

- Joined

- Apr 30, 2015

- Messages

- 11,328

OK I'm always available for questions- correct answers on rare occasions LOL

You can ignore most of that- you'll be connecting the motor direct to the unit

Factory installs sometimes have stringent EMI interference requirements so they use extra filtering/shielding

Hooking up the lathe switches might be a little confusing- I can help there

You can ignore most of that- you'll be connecting the motor direct to the unit

Factory installs sometimes have stringent EMI interference requirements so they use extra filtering/shielding

Hooking up the lathe switches might be a little confusing- I can help there

Last edited:

On the mill I found using the original drum switch to be very easy but that VFD is much easier to work with. I connected the VFD to the drum switch with 20ga shielded control wire. It has on one of the buses FWD, REV and COM and lists the parameter to change to enable external switching and BAM! it worked.

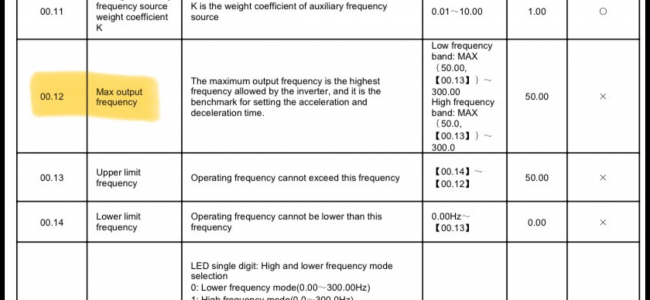

I'm still stuck on setting the default operation to 60Hz. The only thing connected to the VFD at this point is the motor. I attempted to set the upper frequency limit to 90Hz but it wouldn't let me go past 50Hz. My intention was to set a minimum threshold of 30Hz and a max of 90.

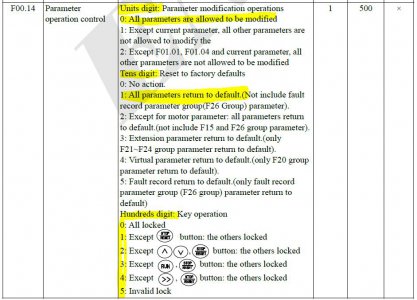

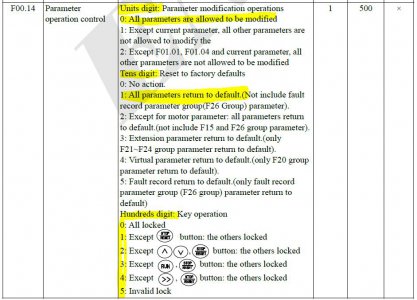

Then I considered resetting the entire VFD to its factory defaults but stopped because I didn't want to make things much worse. The units and tens digits are easily understood but on the hundreds unit there is nothing that says to me "leave all of the buttons functional."

I'm still stuck on setting the default operation to 60Hz. The only thing connected to the VFD at this point is the motor. I attempted to set the upper frequency limit to 90Hz but it wouldn't let me go past 50Hz. My intention was to set a minimum threshold of 30Hz and a max of 90.

Then I considered resetting the entire VFD to its factory defaults but stopped because I didn't want to make things much worse. The units and tens digits are easily understood but on the hundreds unit there is nothing that says to me "leave all of the buttons functional."

- Joined

- Apr 30, 2015

- Messages

- 11,328

There's probably more than one place to set the frequency- I'll take a look at it also

I'd wait on the factory reset for now

Ciao

I'd wait on the factory reset for now

Ciao

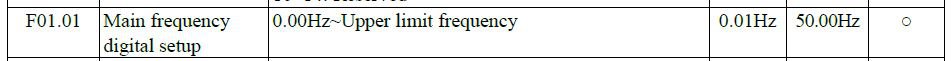

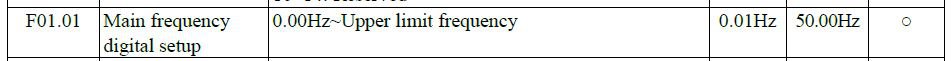

You have to be right about more than one way to set the speed. I’ve spent hours reading the manual without getting any closer to understanding the speed settings. Others have become more clear.

Just to test myself I set some two parameters. I changed the acceleration from 10 seconds to one second and disabled the ramp down in favor of cutting the power completely. That’s one step closer to enabling the footbrake as a bonus. I had zero issues changing them. Bottom line, the VFD is capable of taking new parameters and I didn’t forget how to enter them. That adds a little confidence.

Just to test myself I set some two parameters. I changed the acceleration from 10 seconds to one second and disabled the ramp down in favor of cutting the power completely. That’s one step closer to enabling the footbrake as a bonus. I had zero issues changing them. Bottom line, the VFD is capable of taking new parameters and I didn’t forget how to enter them. That adds a little confidence.