- Joined

- Mar 9, 2018

- Messages

- 468

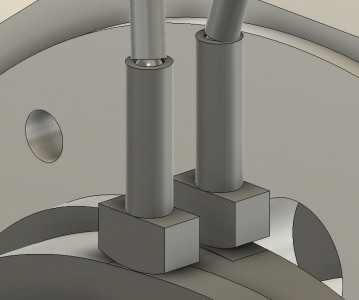

Good input @francist, thanks. You're right with your eyeballed estimate: the remaining gap would only be about 0.045".

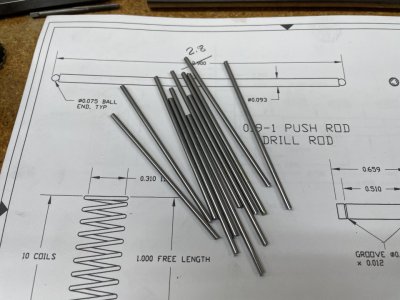

I think what I plan on doing is to make the tappets about 1/8" or so longer than is called for/modeled. That way they can accommodate a bronze tappet guide if I choose to go that route before everything is finalized.

The thing I dread most in adding tappet guides is that I've already reamed out all the holes in the cam housing. So it'd be quite the bit of effort to set the cam housing up on my Bridgeport to be running true, but also to clock it correctly in my dividing head. Doable, sure, but it'd be quite finicky to get it all dialed in right.

I think what I plan on doing is to make the tappets about 1/8" or so longer than is called for/modeled. That way they can accommodate a bronze tappet guide if I choose to go that route before everything is finalized.

The thing I dread most in adding tappet guides is that I've already reamed out all the holes in the cam housing. So it'd be quite the bit of effort to set the cam housing up on my Bridgeport to be running true, but also to clock it correctly in my dividing head. Doable, sure, but it'd be quite finicky to get it all dialed in right.