- Joined

- Feb 25, 2021

- Messages

- 3,130

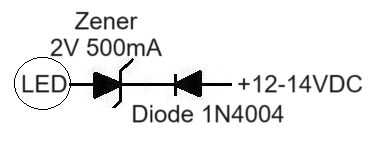

One possible issue is that when the high beams are not on, that wire could be acting like an antenna. Basically an antenna is just that, a wire that is only connected at one end, to the "receiver". If the high beam indicator triggers at some ridiculously low voltage, then when on low beams, the high beam power wire, acting as an antenna, may pick up enough signal from the engine ignition to turn the high beam indicator on.All the wires that are hot with the engine off are hot with the engine running. There is just 1.5 volts more running than not running.

The other noise source is the alternator, which puts out significant ripple especially when the headlights are on. The battery should help reduce that ripple, but again, electrical noise isolation is complex. Since the high beam and low beam wire run in parallel, the amount of cross talk between them could be significant.

Check that high beam indicator wire with the engine running, to see how much voltage is on it, when the lights are on low. Check both AC and DC volts.