A couple of comments on your parameters.

You should set the VFD to the motor specific parameters, PD141-144

Other suggests changes:

PD000 = 0

PD001 = 0

PD002 = 0

PD003 = 60.0

PD004 = 60.0

PD005 = 60.0 or 70.0

PD006 = 3.0

PD007 = 2.0

PD008 = 240

PD009 = *

PD010 = 15.0

PD011 = 4.00

PD023 = 1 (reverse rotation enabled if needed)

PD024 = 1

PD026 = 1

PD041 = 12

PD141 = 230

PD142 = 13.2

PD143 = 1725

PD144 = 4

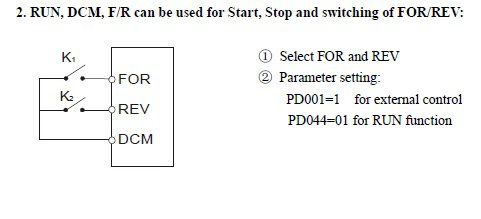

When changing the frequency or stopping, you may need to enter the change for it to take effect, also the voltage and frequency parameter must support these changes, not sure why you would want a variable speed or reverse on a compressor. If it is still not responding to commands you could program/change the multi-inputs and try something like a 3 wire control with external switches. If you are not using the multi-inputs might try setting PD044-PD049 to 0. Do not have access to my notes on the VFD, so there may be a few other parameters that could be tweaked.

Not a big fan of this brand of VFD because of poor documentation and issues like these, but there is nothing close in this price range. I have been able to get them to work correctly, but I have heard that those sold on eBay may be missing their braking module, and have other support/warranty issues, which include the seller disappearing.

View attachment 107316