- Joined

- Jun 7, 2013

- Messages

- 10,160

I am posting some details on my machine:

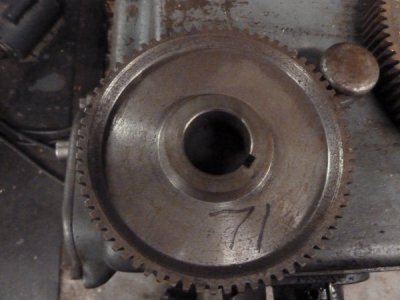

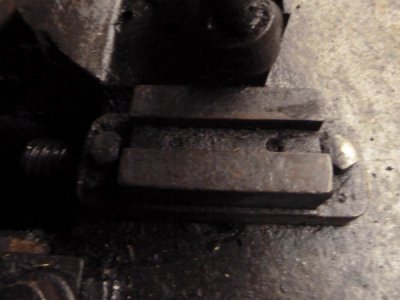

#1cutter arbor gearbox

#2 feed return selector-- allows carriage to rapid travel all the way to the feed gearbox.

#3 index latch; when the pawl is withdrawn, it disengages the indexing motion.

#5 Index selector, when pulled out and rotated to different positions, it selects 1, 2, or 4 turns of the change gear input shaft.

# 6 Same as #2, but shows trip dog and striker.

#7 latch on feed knob; when swung into position over the feed knob rod, it disengages the feed, it being necessary to lever the mechanism manually to accomplish the task; more on this later.

#8 shows the latch swung into position to disengage the feed; this can also be done by pushing/pulling the feed speed selector knob on the left side of the machine to an in between position.

#9 shows the arbor support bracket; mine has just the one bolt to secure it, yours has 4 bolts in addition to the central bolt.

#10 Shows the index fine adjustment so that a gear may be perhaps recut after securing to the arbor, then lining up the tooth space with the cutter, also there is a bolt on the bottom, which when loosened allows the worm to be swung out of engagement with the worm gear.

#1cutter arbor gearbox

#2 feed return selector-- allows carriage to rapid travel all the way to the feed gearbox.

#3 index latch; when the pawl is withdrawn, it disengages the indexing motion.

#5 Index selector, when pulled out and rotated to different positions, it selects 1, 2, or 4 turns of the change gear input shaft.

# 6 Same as #2, but shows trip dog and striker.

#7 latch on feed knob; when swung into position over the feed knob rod, it disengages the feed, it being necessary to lever the mechanism manually to accomplish the task; more on this later.

#8 shows the latch swung into position to disengage the feed; this can also be done by pushing/pulling the feed speed selector knob on the left side of the machine to an in between position.

#9 shows the arbor support bracket; mine has just the one bolt to secure it, yours has 4 bolts in addition to the central bolt.

#10 Shows the index fine adjustment so that a gear may be perhaps recut after securing to the arbor, then lining up the tooth space with the cutter, also there is a bolt on the bottom, which when loosened allows the worm to be swung out of engagement with the worm gear.

![IMG_3891[1].JPG IMG_3891[1].JPG](https://www.hobby-machinist.com/data/attachments/241/241059-45dd24a30aacc61d8dd6e41447e64a71.jpg)

![IMG_3893[1].JPG IMG_3893[1].JPG](https://www.hobby-machinist.com/data/attachments/241/241060-f9c85a3b2f6d0c3b3c5b07a6482a9c51.jpg)

I know back in the day this machine cut it's share of gears for the mills around here.

I know back in the day this machine cut it's share of gears for the mills around here.![IMG_3899[1].JPG IMG_3899[1].JPG](https://www.hobby-machinist.com/data/attachments/241/241087-cec14dcc4c36a9b6279070a730612627.jpg)

![IMG_3900[1].JPG IMG_3900[1].JPG](https://www.hobby-machinist.com/data/attachments/241/241088-c0fdc226eda2ca0d6bbdb32d6f9be9a2.jpg)

![IMG_3901[1].JPG IMG_3901[1].JPG](https://www.hobby-machinist.com/data/attachments/241/241089-d20d559ec2d6c21f20d9e3584089a6b4.jpg)

![IMG_3902[1].JPG IMG_3902[1].JPG](https://www.hobby-machinist.com/data/attachments/241/241094-3ce978721a75d1948dac09c824f892a6.jpg)