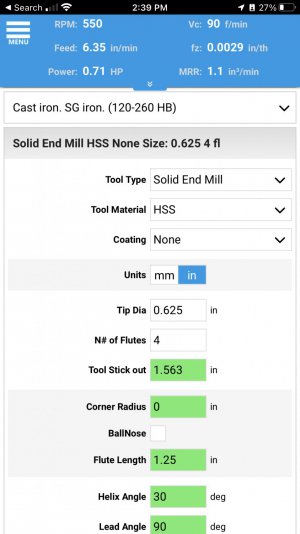

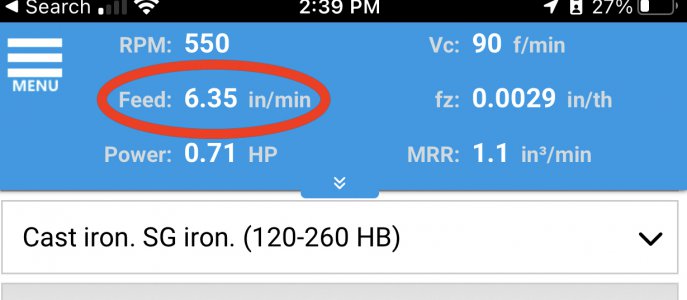

I have a Chinese power feed on my induma mill that I've used for a couple years. I always set the power feed speed by 'feel' usually almost as slow as it will go. Lately I have been getting braver at pushing the mill feeds and speeds so I've been thinking.... How do YOU set the feed rate on the power feed? I have tables that tell me the feed rate but have never figured out how to get the speed they tell me. The power feed gives no feedback on how fast it's going so I have no clue how fast it's moving!

Sent from my Pixel 6 Pro using Tapatalk

Sent from my Pixel 6 Pro using Tapatalk