- Joined

- Jan 1, 2017

- Messages

- 31

***Edit***

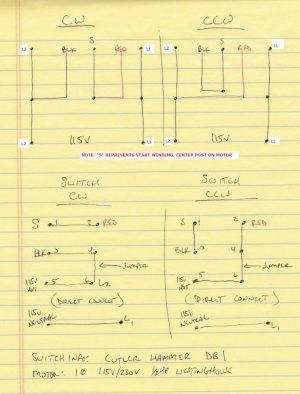

Drum switch wiring has been resolved. See post #4 (http://www.hobby-machinist.com/thre...tage-motor-to-115v-1-phase.54152/#post-449303) for wiring diagram. New issue is trying to switch the motor over to 115v

***Edit***

So I've been rebuilding a new to me Zip-Cut vertical mill over in the Restoration Forum and its time to wire up the motor.

In hopes that it was wired correctly from the previous owner, I cleaned up the terminal ends and tried it out. No dice. Only CCW rotation and it sounds terrible when trying to reverse the switch (which still spins the motor CCW)

I am able to wire the switch to start the motor without issue. I can also get the motor to reverse direction by switching the black and red wires inside the motor itself.

How do I wire the switch to enable either direction?

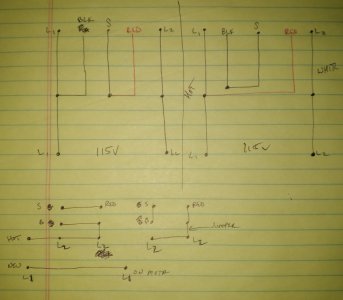

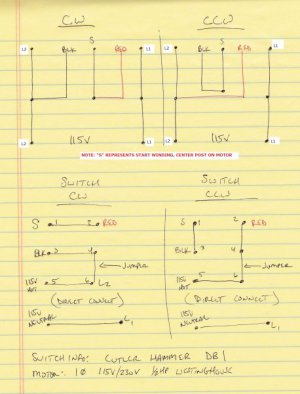

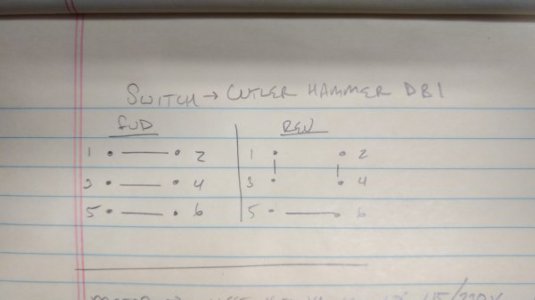

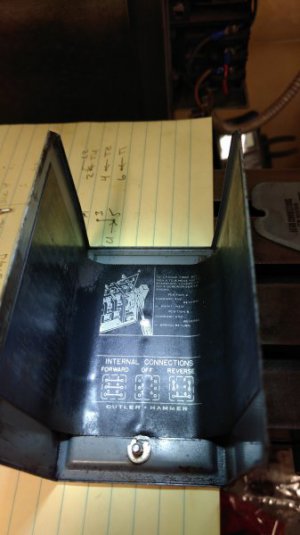

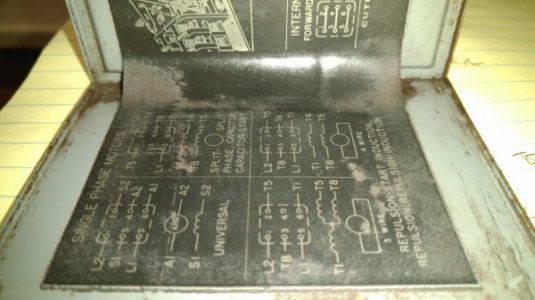

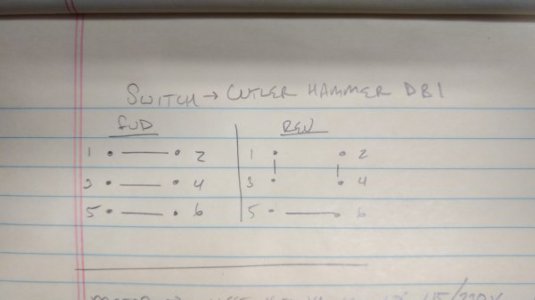

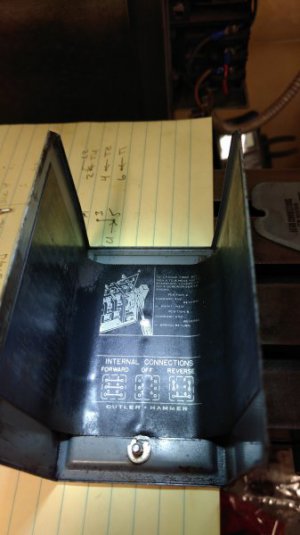

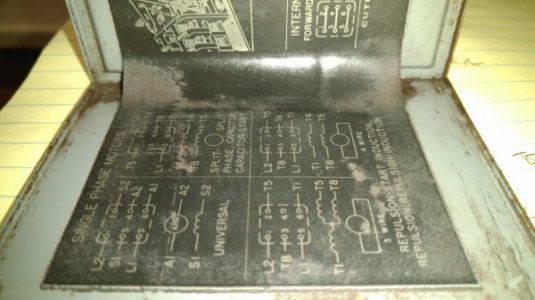

Here are the wiring diagrams

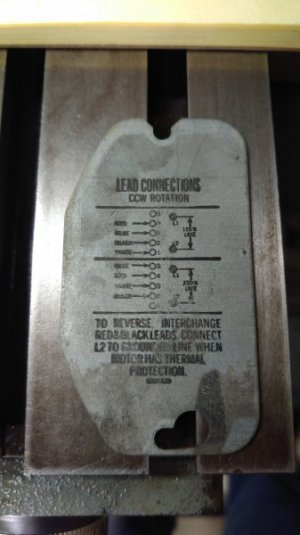

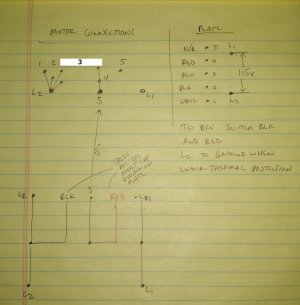

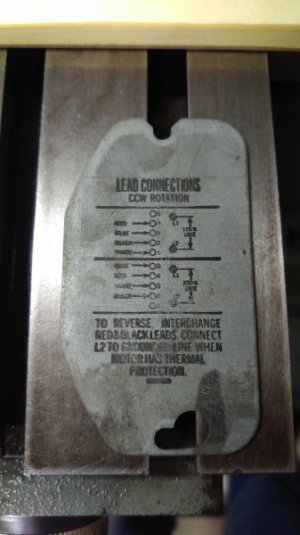

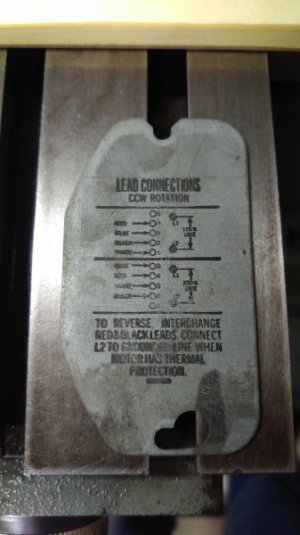

Here is the original motor wiring. To reverse direction I swap the small red wire with the small black wire.

Thanks in advance! If anyone needs better pictures or clarification I will do my best to provide it.

Drum switch wiring has been resolved. See post #4 (http://www.hobby-machinist.com/thre...tage-motor-to-115v-1-phase.54152/#post-449303) for wiring diagram. New issue is trying to switch the motor over to 115v

***Edit***

So I've been rebuilding a new to me Zip-Cut vertical mill over in the Restoration Forum and its time to wire up the motor.

In hopes that it was wired correctly from the previous owner, I cleaned up the terminal ends and tried it out. No dice. Only CCW rotation and it sounds terrible when trying to reverse the switch (which still spins the motor CCW)

I am able to wire the switch to start the motor without issue. I can also get the motor to reverse direction by switching the black and red wires inside the motor itself.

How do I wire the switch to enable either direction?

Here are the wiring diagrams

Here is the original motor wiring. To reverse direction I swap the small red wire with the small black wire.

Thanks in advance! If anyone needs better pictures or clarification I will do my best to provide it.

Last edited: