If you got the same kit I did, the manual should be fairly clear on almost everything. Mine has step by step examples for using all the various functions and the like. It has no Ingrish, just clear English.

I downloaded the installation manual from Grizzly since my kit did not include any info.

To enter set up, just turn it on and hold down the period button with in a second of start up. The first thing to display is resolution, mine was set to 5, change it to 1 if you have 1um scales. I was having trouble setting this on my latest DRO until I realized it was set to metric instead of imperial. Just keep hitting the up or down button to scroll through the options. You exit set up by scrolling to "quit" and hitting enter or whatever passes for it. The only thing I had to adjust was resolution and direction for the x-axis scale.

You might need some aluminum angle and strip. It is expensive to buy from Lowes, get it from online metals or something if you have the time. I also needed some longer 4mm and 5mm screws.

Plan for either a single full day or 3 days in the evening. Try to keep the readheads fixed and have the scales move. If you must move the read head, add strain relief to the wire. Don't forget to add space above the scale for mounting the cover.

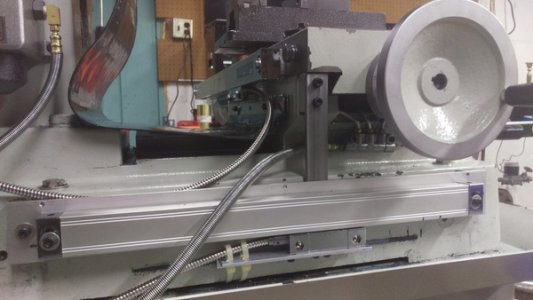

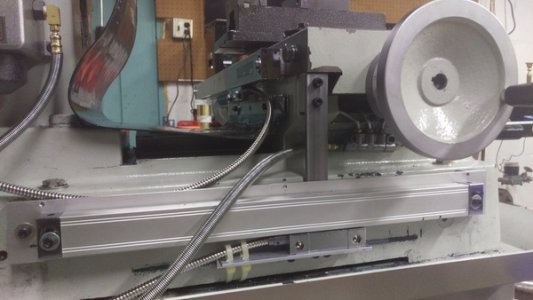

The x-axis read head is bolted to the casting with a machined spacer. The x-axis scale is spaced away from the table to allow oil from the ways to bleed past.

The y-axis scale is bolted to an aluminum strip. The strip has wedge shaped spacers that have slots milled in them. By moving the spacer up and down, the strip can be aligned parallel to the axis. The base casting itself is not parallel to the y-axis, so one wedge had to be slightly thinner than the other. The read head is screwed from underneath to a piece of angle that is in turn bolted to the arm coming down from the moving part. It was a tight fit, and I had to pre-assemble it.