- Joined

- Mar 26, 2014

- Messages

- 211

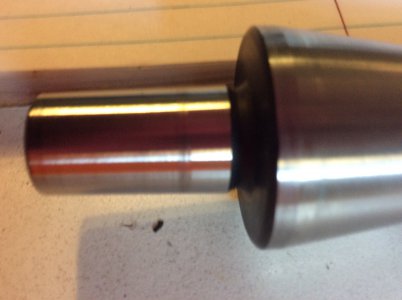

Good evening. I have a couple new drill chucks and arbors where th chuck won’t stay attached to the arbor. Both Chinese, one came with my g0704. Grizzly did replace that one. The other I ordered for my lathe. I’ve attached photos of the one from Grizzly where I showed them it was contacting a small part of the arbor. I tried matching by grinding with valve grinding paste but it still came loose. I thought about matching a small section off the bottom to see if it would set a little deeper but I don’t think it would make a difference. Any ideas?

(Sorry for the poor quality of the one photo. It shows the contact after very lightly rotating to show the first contact point)

(Sorry for the poor quality of the one photo. It shows the contact after very lightly rotating to show the first contact point)