What is the proper way to dress or recondition the typical diamond 'brown' wheels used on D-bit tool & cutter grinders? I can't imagine the single point diamond tool on the swing arm is to be used is it? Presumably that tool use is confined to AO wheels? I've seen some videos where a white colored stick is pressed onto the diamond wheel, but it wasn't identified. (It also seemed to go through the stick like it was a piece of chalk). I tried checking Shars the places that sell wheels & TCG's. Unless I missed it, can't seem to find a dressing stick that specifically says 'for diamond'. There seem to be some internet hits but not exactly as abundant as the wheels themselves, which is odd. And most say 'aluminum oxide' as the main ingredient?

www.falcontool.com

www.falcontool.com

www.falcontool.com

www.falcontool.com

Dressing Sticks for Diamond Wheels, CBN & PCD | Falcon Tool - FALCON Tool Company

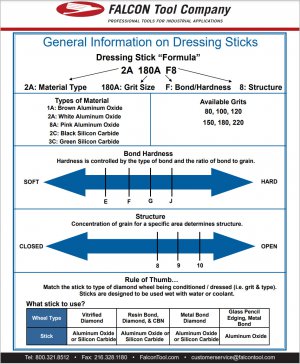

Dressing sticks for PCD, CBN, Resin and Metal Bonded Diamond Wheels. Made of premium aluminum oxide and silicon carbide for consistent quality output.

Dressing Sticks for Diamond Wheels, CBN & PCD | Falcon Tool - FALCON Tool Company

Dressing sticks for PCD, CBN, Resin and Metal Bonded Diamond Wheels. Made of premium aluminum oxide and silicon carbide for consistent quality output.