- Joined

- Dec 3, 2017

- Messages

- 1,909

Yeah I get it. Been kicking around here for years, and still need advice. Sorry. I'm slow.

I'm making something for my Dad. He looked for two years to find this weight. I figure now is the time to make sure I'm not going to ruin anything. Tolerances on this are pretty well non existent, but I don't want it to be ugly. And I don't want to make a mistake that'll ruin it.

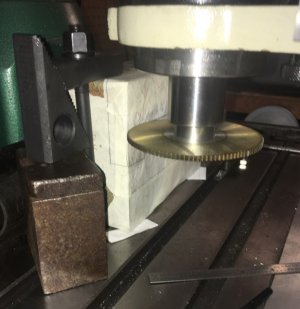

I'm about to very slowly feed this 1/8" thick 4 1/4" milling cutter held in an R8 slitting saw arbor 5/8" deep into this block of cast iron with a spindle rpm of 140 and then run it 9" across. That's the bottom limit for rpm. The calculator says I'm spinning about twice as fast as I should.

Option 1 is do it and see what happens.

Option two is use a .045 thick slitting saw that isn't large enough to get 5/8" deep.

Option three is whatever you all can agree on.

Does it look like my clamping is sufficient?

All input welcome!

I'm making something for my Dad. He looked for two years to find this weight. I figure now is the time to make sure I'm not going to ruin anything. Tolerances on this are pretty well non existent, but I don't want it to be ugly. And I don't want to make a mistake that'll ruin it.

I'm about to very slowly feed this 1/8" thick 4 1/4" milling cutter held in an R8 slitting saw arbor 5/8" deep into this block of cast iron with a spindle rpm of 140 and then run it 9" across. That's the bottom limit for rpm. The calculator says I'm spinning about twice as fast as I should.

Option 1 is do it and see what happens.

Option two is use a .045 thick slitting saw that isn't large enough to get 5/8" deep.

Option three is whatever you all can agree on.

Does it look like my clamping is sufficient?

All input welcome!