- Joined

- Jan 27, 2017

- Messages

- 184

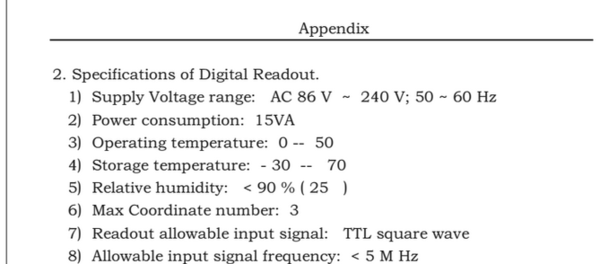

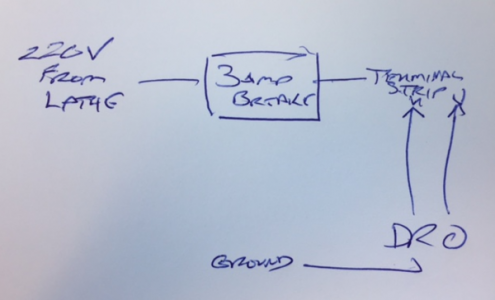

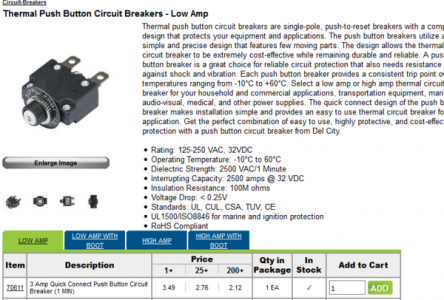

I am planning the installation of a DRO (Sino SDS6-2V) on my lathe (PM1236). The literature indicates that the input voltage is 85V-250V and it appears that the power supply is internal (i.e. no black box plug).

Any reason why I shouldn't be able to direct wire to the lathe. I have seen this mentioned on other threads but wondered if there are any considerations that I should be aware of.

Thanks in advance for any input.

Mark

Any reason why I shouldn't be able to direct wire to the lathe. I have seen this mentioned on other threads but wondered if there are any considerations that I should be aware of.

Thanks in advance for any input.

Mark