- Joined

- Sep 8, 2019

- Messages

- 4,392

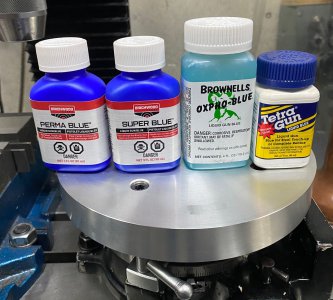

I have 3 quantity CXA tool holders that I need to gun blue. I have a new container of gun blue, but the amount of liquid in there wouldn’t even be enough to cover one of the tool holders.

I don’t mind doing the tool holders separately.

I am wondering if I should dilute the gun blue or wait/save up/buy a larger container of gun blue? I anticipate a fair amount of gun bluing in my future.

If I do dilute it, what would I dilute it with (I will Google this)?

EDIT: I see that one dilutes the cold blue solution with water, but I’m going to watch some YouTube videos because this process looks to be more involved than I had anticipated.

I don’t mind doing the tool holders separately.

I am wondering if I should dilute the gun blue or wait/save up/buy a larger container of gun blue? I anticipate a fair amount of gun bluing in my future.

If I do dilute it, what would I dilute it with (I will Google this)?

EDIT: I see that one dilutes the cold blue solution with water, but I’m going to watch some YouTube videos because this process looks to be more involved than I had anticipated.

Last edited: